Recently I got a new motorbike

and on my second trip out, with only 50 miles on the clock the

rectifier/regulator unit failed. The battery on a bike is

pretty small and with the head light permanently on and all the

ECU, ignition and fuel injection stuff it didn't take long to

run the battery flat. Fortunately I'd stopped and there

wasn't enough charge left to turn the engine over, but it's

possible for the battery to discharge and the bike to cut-out

while riding - not good.

After a bit of research it

became apparent that this type of failure is common, with the

regulator either not charging the bikes battery, or overcharging

it. Despite the ECU monitoring the voltage it doesn't

generate any indication of a low voltage condition to alert the

rider.

This project aims to provide

the rider with an early warning of a fault to the bikes

battery/charging system by connecting to

the electrical supply on the bike and continually measuring the

voltage. If it goes outside of programmed set points it

alerts the rider by activating an LED.

The design can be

applied to cars as well as motorbikes and could also be used for

other voltage monitoring applications.

Hardware

The circuit use a

PIC12F683

microcontroller

programmed with firmware (see download section) that measures the

vehicle supply voltage using an Analogue to Digital Converter

(ADC) and compares it to set voltage points,

activating the bi-colour LED to alert the rider when the

voltage goes outside the expected normal operating range.

The vehicle supply voltage

feeds IC2, an

LM2931AC-5.0,

Low Drop Out (LDO) voltage regulator IC to power the

microcontroller. This part is

designed for use in automotive applications and can withstand

load dumps and reverse transient. There are

several variants of this part, so make sure to get the 'AZ' or

'AC' variant as these have a +/-3.8% or 2.5% tolerance output. Diode D1 protects the circuit

from accidental reverse polarity of the input supply

voltage. Capacitors C2

and C3

are required to stabilise the regulator as per the datasheet for

the device. The design uses a 47µF

capacitor

for C3, but a 22µF

part can also be used.

The LM2931 was chosen because it is

designed for use on automotive electrical systems where the

electrical supply is quite hostile. For other applications

the following devices could be used as an alternative to the

LM2931.

The LM2931 was chosen because it is

designed for use on automotive electrical systems where the

electrical supply is quite hostile. For other applications

the following devices could be used as an alternative to the

LM2931.

An LM78L05

is cheap and easy to find, it's not ideal but should

work. If you do use it, you can omit C3, but will need to

replace C2 with a 1µF / 25 volt electrolytic.

For a

precision 5 volt LDO regulator look at the

LP2950CZ-5.0, this will need a 1µF / 25 volt

electrolytic capacitor for C2 and 1µF / 6.3 volt or 10 volt

electrolytic for C3.

The status LED is a 5mm bi-colour

common cathode part, We used an HLMP4000 part although any bi-colour LED

should work here. It should have a milky white or defused body since

it needs to 'mix' the red and green to get orange. Clear LEDs don't do this so well.

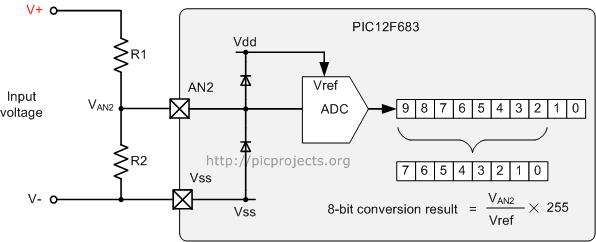

The PIC12F683 contains a 10-bit

internal Analogue to Digital Converter (ADC) that compares the

voltage on the AN2 input (Pin 5) with a reference voltage.

This design uses the Vdd 5 volt supply to the PIC as the

reference voltage (Vref).

Since the range of voltages in a 12

volt automotive system can go up to about 15 volts, and higher

if the alternator regulator fails the input voltage needs to be

scaled down so it falls within the range 0 to 5 volts when

presented to the PIC. This is done using a voltage divider

comprising R1/R2 which are 1% precision resistors to help with

accuracy. There is an optional capacitor

C4 which can be used to filter the input, however this isn't

used here.

Should the supply voltage

exceed 20.16 volts the output from voltage divider R1/R2 will

exceed 5 volts. The PIC has internal clamp diodes on

the inputs connected to Vdd and Vss, the excess voltage will be clamped by the

diode while resistor R1 limits current to just a few milliamps.

Software

The software code the PIC is

running only uses the high order 8 bits of the 10 bit ADC

conversion result. The resolution of the ADC using

8 bits is 5 volts / 255 = 0.0196 volts/bit

(n.b. the firmware actually

checks the 9th bit of the result and uses it to round up/down

the 8-bit result)

The values of R1 and R2 are 10K0 and 3K30 respectively.

This gives a voltage divider ratio of

3K30 / (3K30 + 10K0) == 3300 / 13300 = 0.248

(1:4.03)

Since we are scaling the input

voltage the minimum resolution of the measured input voltage is:

0.0196 / 0.248 = 0.07 volts

So as an example if we have an input voltage

of 12 volts, the output voltage at the junction of R1/R2 seen by

the PICs ADC input will be 12 x 0.248 = 2.977 volts.

The ADC will convert this to a

numeric value which is calculated as ( Vadc / Vref ) x 255

( 2.977 / 5.0 ) x 255 = 152

The maximum voltage we can

measure using a 5 volt reference and 10K0/3K30 divider is:

5 volts / 0.248 = 20.16 volts.

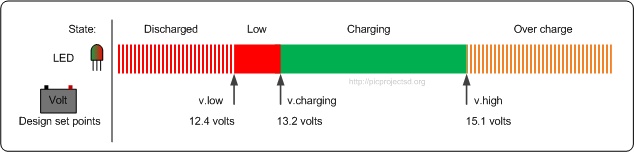

The software program measures

the input voltage around 8 times per second and keeps a rolling

average of the last 8 measurements. The averaged value is compared to

preset values which are used to determine the battery voltage

state indicated by the status LED.

above 15.1 volts

the LED flashes orange ( red+green mixes to give orange)

between 15.1 and 13.2 volts, the LED

is steady green

between 13.2 and 12.4 volts, the LED is steady red

below 12.4 volts, the LED flashes red

The software applies 1 bit (0.07 volts) of hysteresis to these set points.

With a good battery when the

ignition is first turned on the battery should be in the 'low'

voltage range since the engine isn't running the battery isn't

being charged. Once the engine is started the output from

the alternator should bring the battery voltage into the

'charging' range. If it doesn't stay in the charging range

this will be indicated by the LED and should be investigated.

These set points are stored in

the PICs EEPROM and can, if required, be modified either by

editing the EEPROM directly or in the source code.

The value returned by the ADC

for a given input voltage can be calculated using the following:

Set

Point Voltage * (R2 / (R1+R2))

/ (Vref / 255) = ADC Value

Set

Point Voltage * (3.3 /

(10+3.3)) / (5 / 255) =

ADC Value

Example:

14.5 volts x

0.248 / 0.01961 = 183

(hexadecimal 0xB7)

Status LED Mode

While the voltage remains

within the charging voltage range, the green LED will turn off

after approximately 15 seconds. If you want the LED to

remain on continually connect GPIO5 (pin 2) to ground. On

the PCB there are two pads which can be bridged with a solder

blob to ground this pin (circled red, see image right)

Calibration

The values of the three design set points are calculated based

on the resistors R1 and R2 being exactly 10K0 and 3K30 ohms and

the voltage reference exactly 5.00 volts. In the

real circuit the resistors are only accurate to within 1% and

the LM2931 accurate to +/-3.8% so the firmware needs a one-time calibration before use.

This is done by fitting JP1 then powering up the circuit from a

variable power supply. The variable power supply is

adjusted until the voltage measured at the input to the ADC (pin

5) using a precision voltmeter is exactly 2.50 volts. Once set, the jumper is removed

and the PIC calculates and saves a correction multiplier. The

multiplier value is then applied to the set points during normal

operation.

Summary

1. Fit jumper / link between GPIO4 (pin3) and Gnd.

2. Power circuit up using variable output PSU.

3 Adjust board supply voltage until voltage at AN2 (pin 5)

is exactly 2.50 volts.

4. Cut/open jumper on GPIO4 (pin 3).

5. The Status LED will flash to show the 9 bit calibration

value

This repeats until reset/power cycled

Read

as MSB to LSB, Red =0, Green = 1, Orange =end

Read

as MSB to LSB, Red =0, Green = 1, Orange =end

This repeats until reset

or power cycled.

This is for information only and you don't need to do

anything with this.

6. Remove power to circuit and reapply (or reset PIC).

You can do the calibration as many times as you want so if

you mess up, or just want to have dummy run you can. Just

repeat steps 1-6 each time you need to calibrate it.

You can do the calibration as many times as you want so if

you mess up, or just want to have dummy run you can. Just

repeat steps 1-6 each time you need to calibrate it.