| |

|

4

Channel DMX512 Driver

for PIC16F1823

|

|

4-channel DMX512 PWM LED

Driver Board

|

-

The original

DMX512 driver project #800 is now redesigned to incorporate the optional address configuration switch on the main PCB.

-

The

no-switches in-band DMX configuration feature is still

retained

-

Double sided PCB has resulted in a more compact

board size.

-

Firmware has

been updated to run a latest generation

enhanced midrange PIC16F1823 processor.

|

Description

This project is a 4 channel

DMX512 driver board. It features four power MOSFETs that

can be configured to operate in PWM mode or as on/off outputs.

The driver can be configured to use any four consecutive

addresses across the full 512 channel address range. It can drive LED arrays or low voltage lamps with either an 8

bit (256 step) PWM dimming signal or digital on/off mode under

DMX control.

Feature list:

In keeping with the original

4-channel DMX driver project #800, the firmware supports a

minimal external hardware design.

Although the new PCB805B has a

configuration DIP switch on the board, the DMX base address and

configuration modes are stored in the microcontrollers internal

non-volatile EEPROM. Once settings have been made the

firmware uses the saved settings from the EEPROM if no DIP

switch is detected.

Additionally the original

configuration via in-band DMX channel data is still supported.

Fitting a single jumper puts the firmware into 'in-band' configuration mode. DMX

data sent in the first four channels is saved to the EEPROM

allowing the DMX base address and configuration word to be setup

without the use of the external DIP switch.

Download PDF

manual

The project page for the

previous version of the 4-Channel DMX driver can be found here:

Previous

4-Channel DMX driver

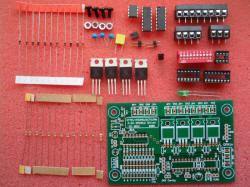

The following options for

the DMX512 PWM Driver are available to buy from

the

Picprojects eShop

- Complete kit of parts,

including PCB and pre-programmed PIC microcontroller, order

code #805K

- PCB805 only, order code

#805P

- PIC microcontroller

pre-programmed with DMX firmware, order code #PRG805

Component List

|

I no longer have

kits or the PCB805 for this project.

|

|

Component |

Description |

|

R1,R2,R3,R4 |

120R 0.125 watt

|

|

R5,R6,R7,R8,R10,R11 |

10K 0.125 watt |

| R12 |

330R 0.125 watt |

| R13 |

120R ( 0.25w or

0.5 watt) |

| R14 |

1K0 0.125 watt |

| R9 |

not used |

All

resistors are 5% carbon film.

Where 0.125 (1/8) watt parts are specified these are required

to fit on the PCB due to size constraints. |

| |

|

| C1 |

330nF polyester (5mm

pitch) (or 470nF) |

| C2,C3,C5 |

100nF multilayer

ceramic (2.5mm pitch) |

| C4 |

not used |

| |

|

| D1-D11 |

1N4148 diode |

| IC1 |

PIC16F1823-I/P

(Must be programmed with DMX firmware) |

| IC2 |

78L05 voltage

regulator |

| IC3 |

MAX481 (or equivalent

RS485 transceiver) |

| IC4 |

HCF4017B |

|

Q1,Q2,Q3,Q4 |

STP20NF06L logic level

N-MOSFET (STP36NF06L alternate part) |

| LED1 |

5mm LED green |

| |

|

| SW1 |

10-way DIP switch |

| CN1 |

5-pin 0.1" header (not

used) |

| ICSP |

5-pin 0.1" header (not

used) |

| CN2 |

2-pin 0.1" header (not

used) |

| JP1 |

2-pin 0.1" header |

| TERM |

2-pin 0.1" header |

| |

2,54mm jumper links

for shorting JP1 / TERM header |

| |

|

| DMXin |

3-way, 5mm,

screw-terminal |

| Power-in

terminal block |

4-way, 5mm,

screw-terminal, 16 amp (2 x 2-way end stackable) |

| Channel

output terminal block |

8-way, 5mm,

screw-terminal, 16 amp (4 x 2-way end stackable) |

| |

|

| IC1 socket |

14-pin DIP socket |

| IC3 socket |

8-pin DIP socket |

| IC4 socket |

16-pin DIP socket |

|

Miscellaneous item x 4 |

M3 nut + M3 x 6mm

machine screw (to mount MOSFET to PCB) |

Notes:

- Apart from resistor R13

all other resistors are 0.125 (1/8) watt parts. These

are specified for physical space constraint reasons on the

PCB.

- The output driver MOSFETs Q1-Q4 are STP36NF06L or

STP20NF06L. These

are logic level devices designed to operate with a low gate

drive voltage. If an alternative non-logic level part is

substituted you may need to derate the maximum output

current per channel.

- Alternative pin-compatible

parts exist for the RS-485 transceiver, IC3.

- SP485 (EXAR)

- ST485 (ST)

- MAX483 (Maxim)

- MAX485 (Maxim)

- other parts are also available

- The

PIC16F1823-I/P (IC1)

requires programming with the DMX firmware.

Construction notes:

- Please read through

this section at least once before starting assembly of the

PCB

- Assembly is

straightforward. You will need previous experience

soldering electronic components, a suitable soldering iron,

hand tools and a multi-meter.

- All photographs in the

section link to a hi-res 1024x768 image for more detail.

- Refer to the

schematic diagram

and component listing above for component values used in this

project

|

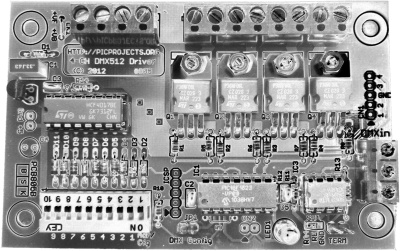

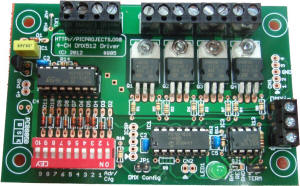

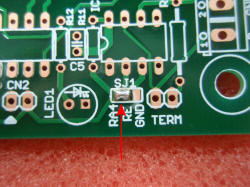

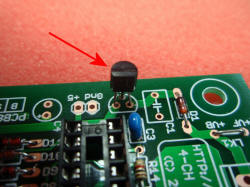

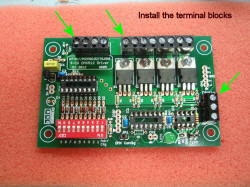

Fig.1 |

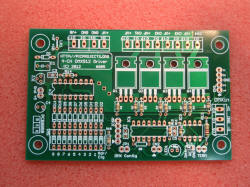

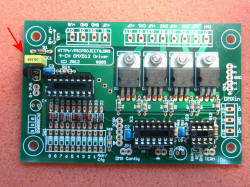

Fig .2 |

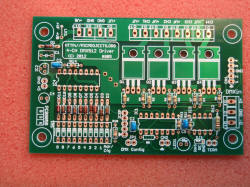

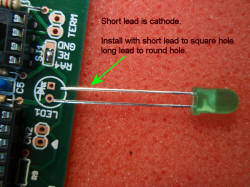

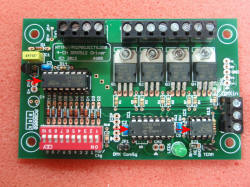

Fig. 3 |

Fig 1.

Make sure you assemble the board in an anti-static work

area and follow ESD handling precautions, particularly

when installing the four MOSFET devices (Q1,2,3,4)

- The MOSFETs are

packed in a separate anti-static bag - don't remove

them until needed.

- IC's 1,3 & 4 are

shipped on black anti-static foam - don't remove

them until needed.

Fig 2. Start by

placing a blob of solder across the RA4-RE pads of SJ1

solder jumper as shown.

Do not allow solder between the RE and GND pads.

Do not allow solder between the RE and GND pads.

Fig 3. Solder

all the resistors in place. It doesn't matter

which way round they go, the colour bands only indicate

the resistance value. It is important that the

correct value resistors are placed in the correct

locations.

The 0.125 watt resistor

are quite small and the coloured bands are not easy to

read. Be sure to identify them correctly (if in

doubt use

a Multimeter on the resistance range setting to check

the value)

120R [brown - red - brown

- gold ] R1,R2,R3,R4,

120R [brown - red - brown

- gold ] R1,R2,R3,R4,

120R [brown - red - brown - gold ] R13 (R13 is the larger

0.25 watt resistor)

120R [brown - red - brown - gold ] R13 (R13 is the larger

0.25 watt resistor)

330R [orange - orange - brown - gold ] R12

330R [orange - orange - brown - gold ] R12

1K0 [brown - black

-red - gold ] R14

1K0 [brown - black

-red - gold ] R14

10K [brown - black -orange

- gold ] R5,R6,R7,R8,R10,R11

10K [brown - black -orange

- gold ] R5,R6,R7,R8,R10,R11

Resistor position R9 is not used with this project.

Resistor position R9 is not used with this project.

|

Fig.4 |

Fig.5 |

Fig.6 |

| Fig 4.

Fit the diodes D1 to D11. These are all the same

1N4148 type.

Each diode has a black band on one end of the body.

Fit all the diodes so the black band on the diode

corresponds to the white band on the component screen

print overlay. Refer to the photo in Fig 4.

Each diode has a black band on one end of the body.

Fit all the diodes so the black band on the diode

corresponds to the white band on the component screen

print overlay. Refer to the photo in Fig 4.

Fig 5. Install

the three 100nF capacitors to positions C2,C3 and C5.

These are marked '104' on the body.

Fig 6. Install

the four MOSFETs Q1,Q2,Q3,Q4

MOSFETs are static sensitive devices. Avoid

touching the pins and handle by the main body only.

MOSFETs are static sensitive devices. Avoid

touching the pins and handle by the main body only.

Install the MOSFETs one

at a time.

- Place the pins

through the PCB and then push down on the body of the MOSFET to bend it flat against the PCB.

- Use M3 x 6mm screw

and M3 nut to fix the MOSFET to the PCB as shown.

- When the MOSFET

has been mechanically secured to the PCB, solder all

three pins of the MOSFET to the PCB

Repeat steps 1 to 3 for

each MOSFET.

There is a large area of copper on the PCB required

to carry up to 12 amps of current to the MOSFET, this

will act as a heat sink when soldering the MOSFET pin

connected to ground. This can make it difficult to

solder with a low power soldering iron. Check the

solder joint is well made before proceeding.

There is a large area of copper on the PCB required

to carry up to 12 amps of current to the MOSFET, this

will act as a heat sink when soldering the MOSFET pin

connected to ground. This can make it difficult to

solder with a low power soldering iron. Check the

solder joint is well made before proceeding.

|

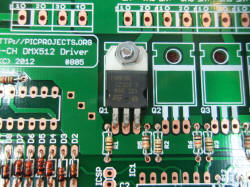

Fig.7 |

Fig.8 |

Fig.9 |

| Fig

7. & 8. Showing installation of the MOSFETs.

Fig 9. Fit

the three IC sockets to the PCB. Make sure all the

pins go through the holes in the PCB and check that none

of the pins have bent

under the socket before soldering.

Each socket has an 'D'

shaped indent at one end. This should align with

the marking on the component screen print overlay.

|

Fig.10 |

Fig.11 |

Fig.12 |

| Fig 10.

Fit the 78L05 voltage regulator to the PCB.

The pins may need

realigning to fit the holes in the PCB. Take care

to position it so the flat part of the body is aligned

with the flat shown on the component screen print

overlay.

Fig 11. Fit the

330nF capacitor C1. This is marked .33J63

(alternative part 470nF marked .47K63)

Fig 12. Fit

LED1. One lead is shorter than the other.

This marks the cathode terminal of the LED. Make

sure to install with the short lead in the position

shown in the photo.

|

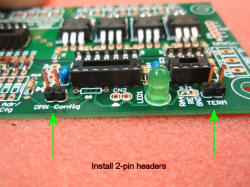

Fig.13 |

Fig.14 |

Fig.15 |

| Fig 13.

Showing LED1 installed on the PCB.

Fig 14. Solder the

2-pin header plugs to positions JP1(DMX config) and TERM

as shown in the photo.

Fig 15. Solder

the 10-way DIP switch to the PCB. Make sure to fit

it so the switch 'ON' position is nearest the edge of

the PCB

as shown in the photo. This will make it easier

to follow the configuration examples in the

documentation.

Before soldering the switch into position check that

none of the leads have bent under the switch instead of

going through the PCB hole. This can happen and if

you discover it after you start soldering the switch in

place it's too late.

Before soldering the switch into position check that

none of the leads have bent under the switch instead of

going through the PCB hole. This can happen and if

you discover it after you start soldering the switch in

place it's too late.

|

Fig.16 |

Fig.17 |

|

| Fig 16.

Fit the 5mm screw terminal blocks to the PCB.

The DMXin connector

uses a 3-way terminal block.

The other two

connectors use end-stackable 2-way connectors to make up

the 4-way and 8-way blocks. If the supplied

connectors are not already stacked together you should

do this before fitting to the PCB.

Fig 17. On the

reverse side of the PCB there is a short length of

exposed copper between the terminal blocks. Tin

this section with solder to increase the electrical

current carrying capacity of the PCB track.

At this stage the assembly of the board is complete.

Give the board a good visual check to make sure all the

solder joints are good, there are no solder splashes or

bridges on any of the joints. Check components are

in the correct location and orientation where

applicable. At this stage the assembly of the board is complete.

Give the board a good visual check to make sure all the

solder joints are good, there are no solder splashes or

bridges on any of the joints. Check components are

in the correct location and orientation where

applicable.

|

Fig.18 |

Fig.19 |

Fig.20 |

|

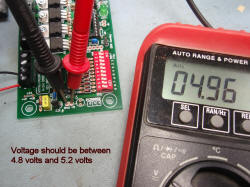

Fig 18.

Before fitting the three IC's into the sockets check the

5 volt power supply to the board.

Connect a suitable DC

power supply to +VB and GND connections of the power

connector terminal block. The power supply output

voltage should be in the range of 9 to 18 volts.

Measure the voltage at

the 5 volt test point on the PCB as shown in the photo.

The voltage measured

here must be between 4.8 volts and 5.2 volts.

If it is not within this range investigate and correct

the fault before proceeding.

Once the 5 volt power

supply has been checked and is working correctly

disconnect the power before proceeding.

Fig 19.

Make sure the board is not connected to the power

supply!

Install

the three ICs into the sockets on the board

- IC1 is a 14-pin

part marked PIC16F1823

- IC3 is a 8-pin

part marked SP485 (alternative part may be

supplied in the kit)

- IC4 is a 16-pin

part marked HCF4017BE

Fit each IC into the

correct socket. Since each IC has a different

number of pins there is only one socket that matches

each device.

Make sure that

each IC is installed with the 'D' shaped indent in the body

matching the indent in the socket. See photo Fig

19.

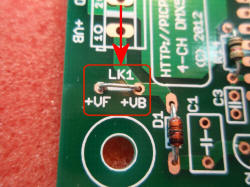

Fig 20. Powering the board.

Fig 20. Powering the board.

The control electronics

on the board require a power supply input in the range 9

volts to 18 volts DC. This is made at the +VB and

GND terminals of the 4-way terminal block.

Since the Channel

Outputs can operate between 3 and 36 volts the board may

require separate power sources for the board and channel

power ( +VB and +VF)

If the Channel Outputs

are operating within the 9 volts to 18 volts range

fitting the link wire to position LK1 will connect the

+VF power input to the +VB board supply, eliminating the

need for two power sources or extra wiring at the

connector terminal.

Only fit LK1 if the +VF power supply is within the 9-18

volt range. Below 9 volts the board will not

operate correctly. Above 18 volts components on

the board may be damaged or destroyed.

Only fit LK1 if the +VF power supply is within the 9-18

volt range. Below 9 volts the board will not

operate correctly. Above 18 volts components on

the board may be damaged or destroyed.

|

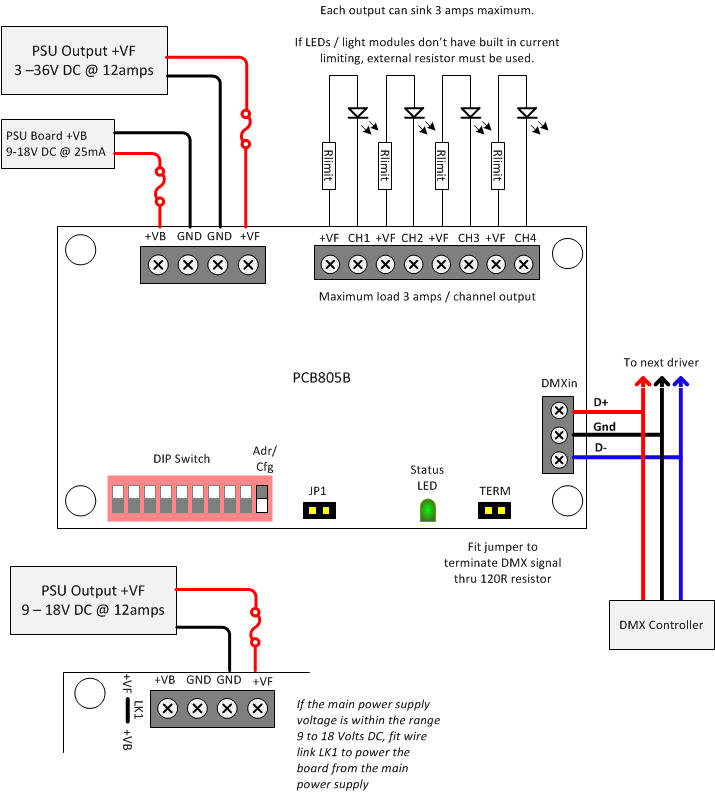

Connecting the board

This is a general

overview of the connections to the 4 Channel DMX512 Driver

PCB805B.

-

When connecting

LED or LED modules to the controller consult the datasheet for

the specific devices being used to ensure voltage and current

limits are met.

-

Do not operate the board at currents or voltages outside the

ranges shown here.

-

Ensure appropriate rated fuses are used in the power supply

connections

-

Ensure correct

wire gauge is used for the current it will be carrying.

-

The +VF

connections shown are all connected to the same common PCB

trace

The GND connections shown are all connected to a common

Ground PCB trace

-

+VF and +VB

are the MOSFET and Board control electronics power inputs

respectively. They are not electrically connected

unless the link wire LK1 is fitted on the PCB. When

fitted LK1 allows the board to derive its power from the +VF

power input. This should only be fitted when the +VF

input voltage is between 9 and 18 volts DC.

|

|

3-pin XLR Wiring for DMX512 |

|

|

Connection for DMX in-out

using 3 pin XLR socket.

There are also

standards for 5-pin XLR and RJ45 connection.

www.dmx512.com |

Configuring Driver Options

Options Summary

The DMX driver board has

various user configurable options as summarised below.

- Output drive mode

The outputs can be

configured to operate in PWM mode or digital mode. Each channel can be individually configured to operate in

either PWM or digital mode.

In PWM mode the channel output is driven with an 8 bit

resolution PWM signal at 200Hz. The duty cycle is

derived from the DMX channel data with 0 = 0% through to 255 = 100%

In digital mode the channel output is either on or off. The DMX channel data controls the output

- Channel data value 0 - output turns OFF

- Channel data values 1-254 - no change at output.

- Channel data value 255 - output turns ON

- Ganged Mode

When Ganged mode is enabled, all four outputs are controlled

by the DMX data in the base address channel

- No DMX signal received

output behaviour

When the driver stops

receiving valid DMX data the outputs can be configured to

either remain in their current state / maintain the PWM duty

cycle, or turn off / set PWM duty cycle to 0%.

The time from the last valid packet being received to

entering the stopped state is approximately 1.5 seconds.

- DMX channel base address

for the driver

Can be set from 1 to 509

As there are 4 outputs on the board the highest base

address that can set is 509 since the fourth output channel

then sees data at the highest DMX address of 512.

Methods for Configuring the DMX

Driver

The driver can be configured

using the following methods:

- using a DMX controller to send the configuration as

in-band channel data.

- On-board DIP switch sets

both DMX base address and configuration modes

Settings made through the DIP switch are saved to the

microcontroller's internal EEPROM.

Since the DIP switch is dual function it is used to set both

address and configuration depending on the position of the

Adr/Cfg switch. This means only one of the two

parameters can be set at any time. The non-active

parameters are therefore read from the internal EEPROM.

i.e. If the DIP switch is set to configure the DMX base address,

configuration modes are then set using the values saved to

EEPROM.

Setting the DMX Base Address and Configuration using In-band DMX

config

The firmware

pre-programmed into the PIC microcontroller also supports

In-band configuration over the DMX data channel. This allows the

address and configuration mode settings to be set in custom

designs that do not use the DIP Switch.

In order to use this method of

configuration the DMX controller must be capable of allowing the

channel data values to be set precisely. Controllers that

don't display the actual channel data value cannot be used

since it's not possible to tell precisely what value has been

set.

To configure the driver using DMX

channel

data:

- Connect a physical jumper

to JP1.

- Cycle power to the board.

- Channel data is read from

the first valid DMX packet received and used to configure

the driver as shown in the table below.

- Once the options have been

programmed into the EEPROM the driver will blink its status

LED in a repeating 2 blink pattern.

- Remove the physical jumper from JP1

- Cycle the power to the

driver to restart using the new settings.

- Watch the status LED to ensure the assigned DMX address

is valid

When JP1 is fitted, regardless of the

currently configured DMX base address, the board will read the data

from the first four channels of the DMX data frame. When JP1 is fitted, regardless of the

currently configured DMX base address, the board will read the data

from the first four channels of the DMX data frame.

-

Channel 1 must contain the value

129 for the firmware to accept the frame.

-

Channel 2 contains the 9th

bit of the binary DMX base address

-

Channel 3 contains bits 8 to 1

of the binary DMX base address

-

Channel 4 contains the

configuration mode byte.

After the firmware receives the

complete frame the DMX address and configuration word are saved

to the microcontrollers EEPROM. The firmware does not do any

validation of the data at this time.

When the data has been written to the

EEPROM the status LED1 will blink twice and this repeats continually

until JP1 jumper has been removed and the power cycled.

When the board restarts with JP1

jumper removed, the firmware validates the DMX address. If it is

not in the range 1 to 509 it will signal an error through the

status LED1.

If a DIP switch is fitted, the address or configuration

mode set in-band will be overwritten by the switch setting at

the next power-cycle after JP1 jumper has been removed.

This can be prevented by setting all the DIP switches to the OFF

position which is the same as having no DIP switch installed. If a DIP switch is fitted, the address or configuration

mode set in-band will be overwritten by the switch setting at

the next power-cycle after JP1 jumper has been removed.

This can be prevented by setting all the DIP switches to the OFF

position which is the same as having no DIP switch installed.

The binary bit positions in the

channel data bytes correspond to the DIP switch

position number shown in the diagram below. To configure

the board with DMX in-band data set the bit positions to '1' or

'0' in the channel data as you would the DIP switch to ON or

OFF.

A ‘0’ in the bit positions

corresponds to the DIP switch number being set to OFF

A ‘1’ in the bit positions

corresponds to the

DIP switch

number being set to ON

Any unused bits should be set to

'0'

DMX Base Address

The driver board

receives data over four consecutive channels starting at the

base address configured on the board. The base address can

be set to start at any address in the DMX packet, however it

also needs to be set to an address compatible with the DMX

controller. Some controllers expect the start address to

be located at fixed offsets, eg. 1, 7, 13, 19, 25...

Refer to your controllers documentation.

Setting the DMX Base Address using the

DIP switch

Adr/Cfg switch should be set to

OFF.

The firmware then uses the rest of the DIP switch to set the DMX

base address.

Switches 9 to 1 are

used to set the binary value of the DMX Base Address used by the

board.

Switches set to the

OFF position correspond to a binary value of 0

Switches set to the ON position correspond to a binary value

of 1

The DIP

switch is only read when the board is powered-on. The address

setting read from the switch is automatically saved to the

microcontroller EEPROM. When no DIP switch is present, or the

switch is set to Configuration Modes, the value previously saved

to the EEPROM will be used.

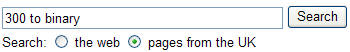

Example: To set the base

address to 300, set switches 9,6,4 & 3 to the on position.

256 + 32 + 8 + 4 = 300

Google will convert decimal to

binary (see example below).

Ignore the leading 0b and set

the switches so 1 = switch ON and 0 = switch OFF

Setting

the Configuration using the DIP switch

Adr/Cfg

switch should be set to ON.

The firmware then uses the

rest of the DIP switch to set the mode configuration for the

driver board.

Action on no DMX

signal received. When no DMX

signal is received the controller can either turn all outputs

off, or continue to drive the outputs with the last PWM or

digital output value for the channel before the DMX data signal

was lost.

Ganged Mode.

In ganged mode all four outputs

use the data from the Base DMX Address.

The table below shows the address used for the channel data

depending on whether the DIP switch is ON or OFF

| |

Channel-1 |

Channel-2

|

Channel-3 |

Channel-4 |

|

Base Address |

ON/OFF

|

ON |

ON |

ON |

|

Base Address+1 |

|

OFF |

|

|

|

Base Address+2 |

|

|

OFF |

|

|

Base Address+3 |

|

|

|

OFF |

Channel Mode.

Each output can operate in either PWM or digital mode. The operating mode can be set for each channel

individually.

In PWM

mode the output is driven with a PWM signal, the duty cycle is set

by the DMX data value:

0 = 0% thru 255 = 100%

In digital mode

the output is either on or off.

-

When the DMX data value is 0 the

output turns off.

-

When the DMX data value is 255 the output

turns on.

-

DMX data between 1 and 254 is ignored and will not

change the output.

Self-Test.

When self-test mode is enabled each output turns on at 0.5

second intervals until all outputs are on (100% PWM duty).

Each output then turns off at 0.5 second intervals until all

outputs are off (0% PWM duty). This repeats continuously until

the self-test DIP switch is set to the OFF position and power is

cycled to the board. During self-test, any data received

on the DMX channel is ignored.

Operation

DMX Channel data

PWM mode

|

Channel |

Value |

Function |

|

|

1 |

0 - 255 |

PWM 0% - 100% |

|

|

2 |

0 - 255 |

PWM 0% - 100% |

|

|

3 |

0 - 255 |

PWM 0% - 100% |

|

|

4 |

0 - 255 |

PWM 0% - 100% |

|

Digital mode

|

Channel |

Value |

Function |

|

|

1 |

0

1-254

255 |

Off

no-change

On |

|

|

2 |

0

1-254

255 |

Off

no-change

On |

|

|

3 |

0

1-254

255 |

Off

no-change

On |

|

|

4 |

0

1-254

255 |

Off

no-change

On |

|

Connectors / Headers /

Jumpers

Board power (+VB / GND)

Input power for the driver

board. 9-18 volts regulated DC @ 25mA

Channel power (+VF / GND)

The MOSFET channel power is

applied to the +VF / GND connector terminals.

Voltage range is 3 to 36 volts DC

Maximum current per channel is 3 amps giving maximum input

power of 12 amps.

The current

rating of the power supply will depend on the devices being

driven. Ensure you use a suitable power supply for

your application.

Note:

If the MOSFET channel power

supply is within the range 9 to 18 volts, fitting the LK1

link wire on the PCB will allow the board to use the +VF

power supply input eliminating the need for two power

sources or extra wiring at the connector terminal.

CH1,CH2,CH3,CH4

Low side switched outputs

connected to the onboard MOSFETS. Channel 1 is

controlled by data sent to the DMX base address of the

board, channels 2,3 and 4 to the next 3 consecutive

addresses.

In Ganged mode all four

channel outputs use data in the DMX Base Address data frame

Do not exceed 3 amps per channel absolute

maximum.

There is no fault

protection on the outputs so depending on your application

you may want to use suitably rated in-line fuses.

DMXin

Connects to the DMX data

cable. Since there are various DMX connector standards

you'll need to wire this to the particular connector you are

using e.g. XLR-3pin, XLR-5pin, RJ45 jack.

TERM

When the jumper is closed,

the DMX signal is terminated into a 120 ohm resistor on the

board. This should only be done on the last board.

Also, if an external cable terminator is used, don't

terminate on the board.

JP1

Open,

normal operation

Closed, enable DMX configuration mode

(see text)

CN1

This 5 pin connector

brings the four channel driver output pins from the

microcontroller to

the edge of the board along with a GND connection.

This makes it easy to interface the driver board to an

alternative output device such as a relay module.

|

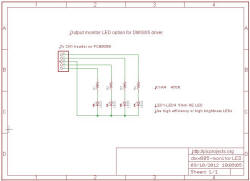

CN1

can also be used to connect four output monitor LEDs to

the driver board. The schematic (left) shows

how this can be done if it is required.

Use high efficiency or

high brightness LEDs with current limit resistors no

lower in value than 470R to ensure the MOSFET gate

drive voltage is not adversely affected.

|

ICSP header

This provides a connection

for In-circuit serial programming of the PIC.

Status

LED

The status LED provides

indication that DMX data is being received during normal

operation and error and status codes if a problem is

detected during start-up.

Note: Since the status

LED shares the same PIC control line as a signal on the ICSP

header when the the board is connected to a PIC programmer

the status LED should be ignored until the programmer is

disconnected.

Normal operation

|

LED |

Explanation |

|

On  |

- DMX data received within the last 1.5 seconds

- At power-on

for ~4 seconds (even if no data received)

|

Blinking 0.5Hz

|

- No DMX data has been received within the last 1.5

seconds

- DMX D+/D-

signal connection reversed.

|

Startup Status Codes

If an error is detected at

power-on the status

LED indicates the detected error condition or status by blinking a number of times followed

by a pause; this repeats continuously. The cause must

be corrected and the driver restarted to clear the condition

and enter normal operation.

| |

LED

blinks |

Cause |

|

2 |

|

Completed a DMX

in-band

configuration. |

|

3 |

|

Invalid DMX base

address. =0 |

|

4 |

|

Invalid DMX base

address. >509 |

|

5 |

|

EEPROM write failed

after 5 retries |

|

6 |

|

PIC internal GPR

memory failed to initialise |

- Status code 2 is not

an error. Once the DMX configuration has

completed, remove the mode jumper and cycle power to the

board to use the new settings.

- Status codes 3 and 4

indicate the DMX base address for the board is invalid.

Re-program a valid address, using either the DMX address

board, DMX in-band configuration

- Status codes 5 and 6.

If these can't be cleared by cycling power to the board,

then the PIC is faulty and should be replaced.

Firmware

DMX805 PWM LED Driver

Firmware

DMX

Compatibility

We've tested the DMX driver

board with the following DMX controllers:

DMX512 test data

transmitter.

This small application

generates 8 frames of DMX data in channels 1 to 8. The

data in channels 1 to 4 increments from 0 to 255 in a repeating

pattern. Data in channels 5 to 8 is always zero.

This code was written to allow

testing of the DMX Driver with a DMX data stream where the

Break, MAB, packet idle time, packet length, etc could all be

configured. This was required since many commercial

products don't generate DMX packets with minimum timing

parameters and it was necessary to ensure the application code

would work reliably under these conditions.

This code has been provided to

allow testing of the DMX Driver described on this web page with

a consistent DMX512 data packet stream. The DMX output

from this code generates a Break of 94uS, MAB of 5.8uS and an

idle time between packets of 5uS. Channel data is sent

back-to-back with no delay.

|

Description |

Filename |

Download link |

DMX transmitter test code

HEX file

ready to program into a PIC16F688 |

dmx688demotx.HEX

V1.0.0 15/10/2012

|

download

download

checksum 7347 |

Example schematic for testing

|