Construction details

for the PCB version are presented in pictures below. The PCB

can be built up to drive either LED clusters or off-board relays but

not both. There are a number of build options which

require a choice to be made as to which parts are installed and

these are described with the accompanying text.

A full component list

and part numbers for Rapid Electronics is provided at the end of the

section.

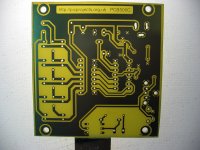

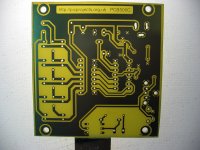

PCB straight from the etch

process |

PCB after drilling. Note the

three holes for the DC power connector (top right) need to

be milled into slots. |

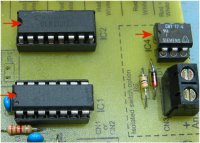

Solder the small components to

the board first. Fit the voltage regulator (IC3) so it

matches the profile on the overlay. You may need to bend its

centre pin out slightly to line up with the holes in the

PCB. |

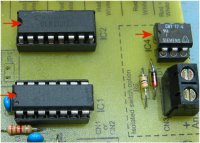

Next install the medium sized

parts. |

C4 needs to be installed with

the negative lead the correct way round.

|

If you construct the circuit

to drive off-board relays,

install wire links into positions JP1 and R1 (circled red).

Do not fit R1 or R2 or the second row of 2 pin header plugs |

The external switch input can

use either a 2 way 5mm screw terminal (shown left) or a

skeleton phono socket [cinch connector] (shown right)

depending on your preference. |

For the LED cluster version

you will need to install R1 and R2. |

After installing R1 and R2 use

the off-cuts from their leads to make the wire links LK2 -

LK5 as shown. |

Assembled board for use with

LED clusters. The optional isolated switch input components

have not been fitted.

For the LED cluster version DO

NOT fit JP1 |

The IC's must be installed

with the small notch as shown.

Also note the black band on Diode D1 |

|

Underside of

the completed board. |

Completed

board with isolated switch input components installed.

Ensure D1 is located with the black band as shown. The

value of R6 needs to be chosen according to the voltage used

in the external input application. |

DC Power input

The board needs a

DC regulated input of 12 volts. Power supply current

rating should be at least 500mA, a 1A supply is preferred.

Do not use an unregulated DC power supply as these generally

only deliver the specified voltage at full load. As the

board has no fuse or over current protection, this should be

provided externally. Typically a regulated DC power supply

will have overload protection built-in and if this is the case

nothing further is required. If you power the circuit from

a battery or other source then you must ensure there is a

suitable in-line fuse.

Switch Inputs

There are two

external switch inputs and an on-board switch. Any of the

switches can be used to operate the unit; you choose which one

depending on your specific requirements.

The on-board

switch is primarily for testing although it can be used for

normal operation if desired. All three switches are

connected to the controller in parallel therefore the use of any

one switch input does not preclude the use of the other two.

SW1 Switch

The SW1 switch on

the PCB can be used for testing the board without any external

switches connected.

The start sequence

is triggered on the release of the switch not the initial press.

Non isolated switch

input

The CN1/CN2

connector provides input for a non-isolated switch to be

connected to the controller.

Isolated switch input option

The isolated

switch input needs its own power source to turn the LED on in

the opto-isolator. If you include the isolated switch

input option you need to select the value of R6 according to the

voltage used in the external circuit.

Suggested values

are shown in the table below. Use a 5% 1/4watt carbon film

resistor. With the values shown the LED current will be

approximately 30-35mA.

|

Voltage (DC) |

R6 |

| 3 |

47R |

| 5 |

100R |

| 6 |

150R |

| 7.5 |

180R |

| 9 |

220R |

| 12 |

330R |

for safety reasons do not

use voltages > 18volts at this input

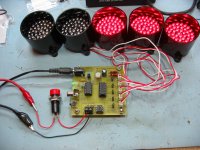

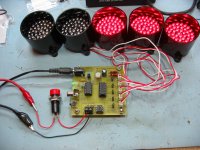

Right. Testing the board

using the isolated switch option.

The red/black crocodile

clips are connected to a bench power supply.

The isolator will work

with various input voltages provided R6 is correctly

specified (see table above)

|

|

LED Clusters

The LED clusters

are

Kingbright type BL0307-50-44.

These contain 50 LED's connected as 10 parallel strings of 5

LEDs as shown in the schematic below. Available from

Rapid Online - Rapid Electronics Ltd., part No

56-2985

Download datasheet for

Kingbright LED

Cluster

Ensure they're connected to the

controller with the red and white leads as shown in both the

photos and indicated on the PCB overlay. The LED

clusters illuminate sequentially from 1 to 5 and this is

indicated on the PCB overlay.

The board will

drive either a single row of 5 LED clusters or two rows.

When using it with two rows, connect the second set of LED

clusters to the second column of 2 pin headers (circled yellow)

in the photo below.

Adjusting

Brightness

When JP1 is open,

the controller drives the outputs using a PWM (pulse width

modulated) signal. This allows the brightness of the LEDs

to be controlled by adjusting the position of PR1. The PWM

frequency is ~350Hz to avoid any visible flickering.

The brightness

control input is an analogue signal varying from 0 volts (dim)

to 5 volts (bright). For the technically minded it is

possible to modify the circuit to use a Light Dependant Resistor

to automatically adjust the LED brightness to match the ambient

lighting.

Drive modes

The software

supports three drive modes of which two are supported on the

PCB. The third mode may be used if you incorporate the

microcontroller into your own hardware design.

The design of the

circuit uses a single current limiting resistor (R1 & R2) for

each row of LED clusters. For this to work only one LED cluster

can be on at any time otherwise the more LEDs that turn on, the

dimmer they get. The software drives each output one at a

time but it does so 350 times a second and through persistence

of vision to the human eye they appear to be on at the same

time. The reason it has been implemented this way is for

two reasons.

-

The total

maximum current required is that of 2 LED clusters rather

than 10 so a smaller and cheaper power supply can be used.

-

The drive

circuit uses a single ULN2003A transistor array and two

resistors which keeps the cost down and the complexity of

the circuit and PCB layout are simplified.

|

Mode |

RA0 (JP1) |

RA4 |

|

|

Direct |

closed (Gnd) |

open |

Use with relays and other devices that can't use PWM |

|

Direct PWM

* |

open |

closed (Gnd) |

Use with LED driver that has individual current

limiting |

|

Multiplexed

PWM |

open |

open |

Use with LED driver that has common current limiting |

The RA0 / RA4 inputs have

internal weak-pull enabled so there is no need for external pull

up resistors.

* On the PCB, RA0 is connected

to JP1 but RA4 is not made directly available since the

Direct PWM mode isn't supported by the hardware on the PCB.

Driving

Relays

If you use the PCB to drive

relays they should be rated for operation at 12V DC and the coil

resistance should be >150 ohms otherwise there is a risk of

damage to IC2 (ULN2003A).

Connect each relay coil to the

2-pin header on the PCB. You'll need 5 relays in total,

one connected to each output.

Also ensure JP1 is closed

otherwise the relays will be driven with a PWM signal and won't

operate correctly.

In the UK all the

components can be obtained from

Rapid Online - Rapid Electronics Ltd.. I've provided a

component list with their part numbers and descriptions. The parts

used are all commonly available and should be obtainable from most good

electronic component distributors anywhere in the world.

Note: where it says

(option)

in the description, you only need

the part if you are building it with the selected option.

| Schematic part |

Qty |

Description |

Rapid Part No |

| LED Clusters |

5(10) |

52MM ULTRABRIGHT

LED CLUSTER (RC) |

56-2985 |

| C1, C3 |

2 |

100N 2.5MM Y5V

DIELEC.CERAMIC (RC) |

08-0275 |

| C2 |

1 |

220N 5MM Y5V

DIELEC.CERAMIC (RC) |

08-0280 |

| C4 |

1 |

100UF 25V LOW

IMPEDANCE ELECTROLY CAP RC |

11-2922 |

| R1, R2 |

1 pack |

PACK 10 10R PR02

2W POWER RESISTOR RC |

62-6708 |

| R3 |

1 pack |

PACK 100 3K3 0.25W

CF RESISTOR (RC) |

62-0382 |

| R4 |

1 pack |

PACK 100 100R

0.25W CF RESISTOR (RC) |

62-0346 |

| R5 |

1 pack |

PACK 100 150R

0.25W CF RESISTOR (RC) |

62-0350 |

| R6 |

1 |

See text

(option) |

- |

| PR1 |

1 |

6MM CERMET

POTENTIOMETE HIGH TEMP 10K (RC) |

67-0354 |

| PWR-ON LED |

1 |

MINIATURE 3MM PURE

GREEN LED (RC) |

55-0107 |

| D1 |

1 |

1N4148 75V 150MA

SIGNAL DIODE. (RC) (option) |

47-3308 |

| |

|

|

|

| IC1 |

1 |

PIC16F684-I/P MICROCONTROLLER (RC)

(Needs programming) |

73-3388 |

| IC2 |

1 |

ULN2003A

TRANSISTOR ARRAY 7 MATCHED (RC) |

82-0618 |

| IC3 |

1 |

DA78L05 V REG +5V

100mA TO-92 TRU (RC) |

47-3612 |

| IC4 |

1 |

CNY17-3 TRANSISTOR

OPTOISOLATOR (RC) (option) |

58-0886 |

| LED cluster plug |

10 |

2 WAY SINGLE ROW

PCB HEADER PLUG (RC) |

22-0520 |

| |

|

|

|

| Socket for IC1 |

1 |

14 PIN 0.3IN DIL

SOCKET (RC) |

22-0155 |

| Socket for IC2 |

1 |

16 PIN 0.3IN DIL

SOCKET (RC) |

22-0160 |

| Socket for IC4 |

1 |

6 PIN LOW

PROFILE IC SOCKET (RC)

(option) |

22-0145 |

| SW1 |

1 |

5.85MM RIGHT ANGLE

TACT SWITCH (RC) |

78-1154 |

| PSU |

1 |

15W MINIPLUG TOP

SM PSU 12V DC 1.2A (RC) |

85-2902 |

| DC Power Skt (J1) |

1 |

2.1MM PCB DC POWER

SOCKET (RC) |

20-0970 |

| CN1 |

1 |

BLACK PCB SKELETON

PHONO SKT (RC) (option) |

22-1122 |

| CN2 / CN3 |

1 |

2 WAY 16A

PCB TERMINAL BLOCK (RC) (option) |

21-0112 |

The PIC 16F684 microcontroller

needs programming before use. Source code and programmer ready HEX

files can be downloaded here.

Download:

Firmware version 1.0.6, release

date 23/05/2008

Not got a programmer? Buy

a pre-programmed PIC from the

On-line store