|

PWM

DC Motor

Controller

for PIC12F683

|

|

Description

There are lots of designs on

the Internet for DC power controllers using Pulse Width

Modulation (PWM) to control the speed of a motor or power to a

resistive load. Most

of these use analogue methods to generate the PWM signal which in

turn drives a power MOSFET or transistor.

When I wanted a speed controller for the PCB drill I use to make

all my PIC Projects what else could I do but design a PWM Power

Controller around a PIC - a practical PIC project for sure.

I came up with a fairly

straightforward design based on a

PIC12F683 using the

Capture/Compare/PWM

(CCP)

peripheral inside the PIC to generate a PWM output. An 'N'

Channel Logic Level MOSFET in a low side configuration is driven

by the PIC to control the output power to the motor.

A variable resistor provides a

voltage input to the PIC which is converted to a digital value

using the onboard Analogue to Digital convertor, this in turn is

used to set the PWM duty cycle. Since the PWM duty cycle

is adjusted using a voltage signal input to the PIC it is

possible to use an alternative analogue front-end instead of VR1

to provide this voltage input and therefore control of the duty

cycle.

|

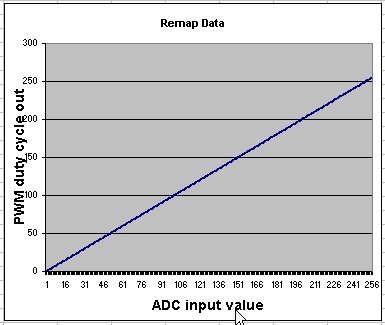

In the original version of

this project the input from the Analogue to Digital

Converter (ADC) was fed directly to the duty cycle

register of the PWM module on the PIC, therefore the PWM

output duty changed linearly in direct proportion to the

change in input voltage to the ADC; much the same as an

analogue PWM. The switch

input allowed the PWM period to be selected in one of

three ranges; 15.6Khz, 3.8Khz and 980Hz.

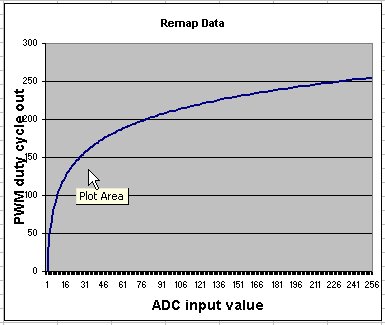

The significant feature in

the new version of the firmware which sets it apart

from analogue PWM is that it now uses the input from the ADC as an index to a

data table. This table contains the required output duty cycle

and period. By creating a suitable table of data

you can map any value at the input of the ADC to any duty

cycle and one of 3 fixed periods at the PWM output.

The switch input now

cycles through 3 mapping tables. The default

tables supplied with the code have a one-to-one mapping

of input voltage to duty cycle output and fixed periods

of 15.6Khz, 3.8Khz and 980Hz respectively to keep it

backward compatible with the original version of the

code.

More details of this and

example map table files can be found in the

Operation section.

A push button cycles through

three different mapping tables. The mapping table in use is saved to EEPROM so it always

powers up using the last selected table; an LED indicates

the current setting.

There is also a digital control

input that allows the output driver to be turned off. When

pulled low the PWM output is set to 0%.

|

Example of log10 map

Example of three map

tables, each with

completely different remap data |

|

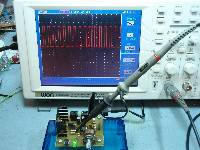

connected to PCB drill |

Showing

PWM signal on oscilloscope |

Code development prototype |

Prototype PCB |

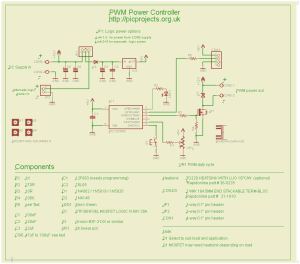

Schematic

Download

schematic in PDF

Circuit Description

The PIC12F683, IC1 has an

internal hardware PWM peripheral that is used to generate the

PWM signal. The duty cycle of the PWM signal is controlled by

VR1 which via R1 presents a voltage on pin 3 of IC1.

With 0V on the input the duty cycle is 0% (off) up to 100% with

5 volts at the input. The PWM signal is output

from pin 5 of IC1 and drives the gate terminal of Q1 through R3.

Resistor R4 connects the gate terminal of Q1 to ground. This ensures that Q1 remains off when the circuit is first

powered on as the I/O pins of IC1 are all set to inputs until

the firmware initialises them as outputs. Diode D1 is

required when driving inductive loads and provides a path for

the inductive flyback current. For loads up to 3 amps Q1

does not require a heatsink, above this you may need to use one.

Power for the logic is provided

by IC2, a 78L05 5 volt regulator. It connects to the input

voltage source via diode D2 which provides protection against

reverse polarity connection of the supply. The 3-way

jumper JP1 allows the input voltage for the 78L05 to be taken from

either the main power

input or an auxiliary supply. When a jumper is connected between pins 1 and 2

power comes from the main DC input.

Since the maximum input voltage for a 78L05 is 30 volts there

may be applications where a separate power supply is needed for

the logic. This is catered for by connecting a jumper between

pins 2 and 3 of JP1 and connecting an alternate power supply to

JP2.

Switch SW1 allows one of three

PWM remap tables to be selected. To avoid accidental

changes to the map table in use the firmware requires the switch

to be held for at least 500mS before switching to the next map

data table. The table selected is indicated by LED1 and the

value is saved to EEPROM so it always powers up using the last

used setting.

CON1 provides a digital input which

is polled by the firmware. When this input goes low the

duty cycle is set to 0% from the start of the next PWM period,

this turns MOSFET Q1 off.

When the input returns high the PWM restarts using the duty

cycle set by the input from VR1. The connector also provides 5v and Gnd connections to allow

connection of a small off-PCB control circuit. If it

is used to power another circuit, ensure it doesn't draw more than

40mA from the supply. If the shutdown control isn't

required, leave the connector open and the PICs internal

weak-pull-up will hold the input high enabling the PWM output.

The circuit as shown will work

with input voltages from 9 to 20 volts. If you choose to

use it with a higher input voltage you may need to select

different components (see notes below)

Notes:

- Since the power controller

can work with a DC input voltage from 9 volts up to 40 volts

or higher the following components need to be suitably rated

for the specific application the controller will be used

for:

- Q1 and D1 need both

voltage and current ratings to suit the application.

- C2,C3,C5,C6 should

have a voltage rating greater than the input voltage.

- IC2 needs minimum of

8.5 volts and absolute maximum of 30 volts.

- Q1 is a logic level MOSFET and

is designed to be driven by a low gate voltage. Standard MOSFETs

will generally work as a substitue in low power applications.

- For the flyback diode D1 a 1N4002 can be used here for

most low power applications, a 1N5819 Schottky is better, for

higher current loads a 1N5820, SB330 or SB350 might be preferred.

- To get the full range of control when VR1 is rotated

fully CCW, check that the voltage on the wiper terminal of

the VR1 is at 0 volts. The voltage on the VR1 wiper

terminal must go from Vss to Vdd to get the full output range.

- Potentiometer VR1 is specified as 5K on the schematic but it can be

substituted with a 4K7 part or a 10K. In all cases it needs

to be a linear (LIN) type not logarithmic (LOG).

- The PIC MCLRE reset input (pin 4 ) is set to input with

the reset logic internally tied to Vdd and a weak-pull up

enabled on the I/O pin.

Limitations

This is a very basic PWM power

controller and it does have some limitations. These are

not design flaws, but the result of the design goal for the

project which was low cost and simplicity. Therefore please note the

following:

- There is no current limit

or overload sensing, you may need to use a fuse inline with

the load.

- The PWM controller is open

loop so it does not adjust the duty cycle to maintain a

constant motor RPM as the load changes. You could add

an analogue PID control loop at the ADC input to achieve

this if it is required.

- The design with components

specified will work at supply voltages up to 20 volts and output

loads around 3 amps, possibly higher depending on whether

the load is inductive or resistive. With

alternate components the circuit could be used with load

voltages and current greater than this. However it

should be noted that since the MOSFET is driven directly by

the output from the PIC, there is a limit as to the

voltage/current and type of loads that can be switched

before it becomes necessary to use a dedicated MOSFET gate

driver between the PIC and the MOSFET.

Photos above show the PWM

output at the three operating frequencies.

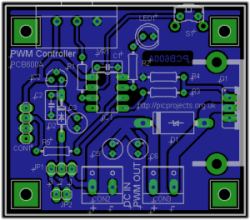

PCB Layout

Download PCB

artwork in PDF

Download Eagle 5.3.0 CAD Files (ZIP)

Component List

You can buy all the parts

needed to build this project from most component suppliers world

wide. In the UK you can get everything from Rapid Online and

I've included a parts list with their part numbers below.

All

Rapid parts/descriptions correct at 16-November-2008. You should

check part# and descriptions are correct when ordering in case

I've made a mistake transferring them onto this page.

Ordering parts from

Rapid?

Use the cut & paste quick order form on their

home page

with this list of

parts

Components in this list are

suitable for use with an input voltage in the range 9-22

volts DC

| Component |

Description |

Part # |

| R1 (order 1

pack) |

PACK 100 1K 0.25W CF

RESISTOR (RC) |

62-0370

|

| R2 (order 1

pack) |

PK 100 270R 0.25W CF

RESISTOR (RC) |

62-0356 |

| R3 (order 1

pack) |

PACK 100 220R 0.25W CF

RESISTOR (RC) |

62-0354

|

| R4 (order 1

pack) |

PK 100 100K 0.25W CF

RESISTOR (RC) |

62-0418

|

| R5 (order 1

pack) |

PK 100 100R 0.25W CF

RESISTOR (RC) |

62-0346

|

| VR1 |

16MM 4K7 LIN.

COMMERCIAL POT. (RC) |

65-0710

|

| C1 |

100N 5MM PITCH CERAMIC

DISC CAPACITOR RC |

08-0235 |

| C2 |

220NF 63V 5MM

POLYESTER BOX CAPACITOR RC |

10-3264 |

| C3 |

22UF 25V TANTALUM BEAD

2.5MM RC |

11-1050 |

| C5, C6 |

47UF 25V LOW IMPEDANCE

ELECTROLYT CAP RC |

11-2921 |

| |

|

|

| D1* |

1N5819 SCHOTTKY DIODE

DO-41 RC |

47-5322

|

| D2 |

1N4148 SIGNAL DIODE

75V 150MA (TRU) RC |

47-3416

|

| Q1 |

STP36NF06L MOSFET

LOGIC N 60V 30A (RC) |

47-0552

|

| IC2 |

DA78L05 V REG +5V

100MA TO-92 TRU (RC) |

47-3612 |

| LED1 |

L-7113GD LED 5MM GREEN

DIFF 20MCD (RC) |

55-0120

|

| socket for IC1 |

8 PIN 0.3IN TURNED PIN

SOCKET(RC) |

22-1720 |

| IC1** |

PIC12F683-I/P

MICROCONTROLLER (RC) |

73-3374

|

| CON1, JP1,

JP2 (order 1)*** |

10W SINGLE

ROW PCB HEADER PLUG RC |

22-0515 |

| CON2, CON3 |

2 WAY 16A

5MM END STACKABLE TERM-BLOC RC |

21-1810 |

| Heatsink

(if needed) |

TO220

HEATSINK WITH LUG 19°C/W (RC) |

36-0235 |

| S1 |

3.85MM

RIGHT ANGLE TACT SWITCH (RC) |

78-1152 |

| Jumper

(use with JP1) |

OPEN BLUE

2.54MM JUMPER LINK (RC) |

22-3555 |

Parts List Notes

*

D1 may need to be

changed for a higher rated part if used with inductive loads at

high currents.

** IC1 will need

programming with the firmware code

before use

*** Order a single 10way

header for CON1, JP1, JP2 and then cut into lengths of

4-way, 3-way and 2-way

There is no capacitor C4,

the component labels jump from C3 to C5

PIC Programmer

If you need a PIC programmer you can also buy the PICkit2 starter kit from Rapid, part #

97-0101

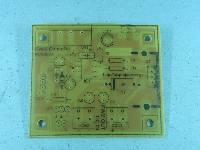

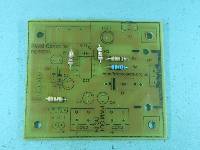

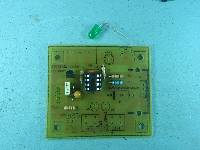

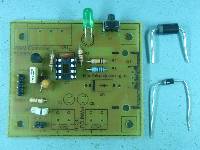

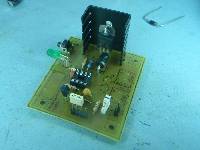

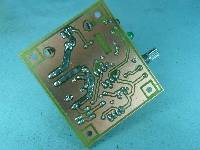

Construction photos:

Fig.1

|

Fig .2 |

Fig. 3 |

Fig.4

|

Fig .5 |

Fig. 6 |

Fig.7

|

Fig .8 |

Fig. 9 |

Fig.10 |

Fig .11 |

Fig. 12 |

Fig 1. Start assembly

with the small components first and work through to the large

parts. Be careful to observe anti-static handling

procedures when installing the MOSFET Q1, to avoid destroying

it.

Fig. 4 The LED has its

legs bent through 90o before installation

Fig.6

Diode D1 depends on the type and power rating of the load.

The PCB will take a large body diode but you can also use the

smaller 1 amp types as your application requires.

Fig.7

Install shorting jumper across pins 1+2 of JP1 as shown.

If you know exactly what how you will be using the controller, a

cheaper option is to simply install a wire link instead of JP1.

Fig.8/9

With loads up to 3 amps Q1 doesn't need a heatsink. Above

3 amps it will need one and even if the load is under 3 amps it

won't hurt to fit one anyway.

You do not need to use an

insulating washer kit between the heatsink and the MOSFET since

the heatsink is isolated on the PCB. However, since the

heatsink is connected to the MOSFET you need to make sure it

doesn't come into contact with any other parts of the circuit or

any enclosure you install the controller into.

Fig.12

Heavily tin with solder the PCB tracks between the

connectors and MOSFET to increase the current carrying capacity

of these tracks. This is shown in the photo.

Operation

Controls

In use, VR1 controls the duty

cycle (and period) of the PWM output. The analogue input

from VR1 is used as an

index to the map table which returns the required PWM duty cycle

and period. This means a linear input at the ADC can

be used to generate a non-linear change in duty cycle at the

output.

An example of where this can be

useful is controlling the brightness of an LED. The

apparent brightness of an LED does not respond in a linear

fashion to increases in duty cycle. By creating a suitable

remap table, a linear change at the ADC input can be remapped to

a duty cycle curve that produces an apparent linear increase in

brightness of the LED.

Another significant feature of

using the ADC input as an index to a lookup table is that not

only does it allow the duty cycle to be remapped but the PWM

period can also vary in response to the input at the ADC.

Taking advantage of the

available memory in the PIC MCU, three remap tables can be

programmed into the PIC. Switch input S1 is used to select the map table to be

used .

Pressing S1 for > 500mS will cycle through three map tables; this is to avoid accidental

operation. The table in use is indicated by the LED as

shown below. The map table selected for use is also

saved to EEPROM so when the PIC is next powered on it will use

that last selected table.

The default map tables supplied

with the code use a linear mapping of input voltage to output

PWM duty cycle. Each table has a fixed PWM period.

| Map Table 1,

PWM period 15.6KHz

Map Table 2, PWM period 3.8KHz

Map Table 3, PWM period

980Hz

Example include files:

|

Linear input to output

duty cycle map |

Alternate Map Tables

The map data used

by the firmware can be changed by editing the

bdcm_remap.asm file and entering alternate include

file names for the required map tables. The

section to edit can be found at the end of the

file (example below). The semicolon comments

the line out, removing it will cause the line to be

included during assembly. There should always

be three remap data files included. These can

be different files or the same one included three

times.

;

---------------------------------------------

; Include up to 3 remap data include files here

;

; ---------------------------------------------

; 1st include -> remapSelect 0 -> LED on

#include

remapData1.inc

; 2nd include -> remapSelect 1 -> LED 6.2Hz

#include

remapData2.inc

; 3rd include -> remapSelect 2 -> LED 1.5Hz

#include

remapData3.inc

;#include remapData4.inc

;#include remapData5_log10.inc

New tables can be

created using a spreadsheet. Copy and past the required

cells into MPLAB and save as someMapFile.inc.

Include the names of the map files in the bdcm_remap.asm

file and reassemble.

Example spreadsheet

table (Excel 2003)

The duty cycle value used in

the map table should be a integer in the range 0 to 255.

To convert the duty cycle as a percentage to a value for the map

table, multiply by 2.55

e.g. 60% x 2.55 = 153

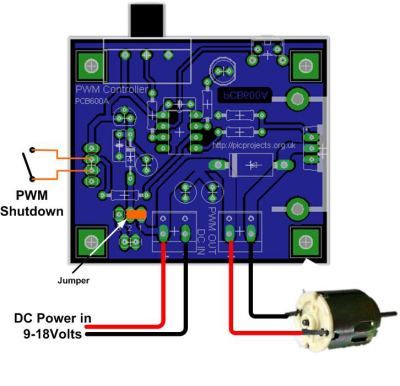

Connecting the PCB

Connect DC input power to CON2

and the output load to CON3. The PWM Shutdown input is

optional, if it's not required leave the connector disconnected

and the output will be enabled.

Safety

Warning:

The shutdown control input should not be used as

an emergency stop. |

Firmware

The HEX file is ready to

program directly into a PIC 12F683. The asm file contains the

source code which you can modify or just view to see how it

works. If you are going to modify the code I recommend you

download and install the

Microchip MPLAB IDE which will allow you to edit, modify and

program the PIC seamlessly.

If you need a PIC Programmer I

strongly recommend the

Microchip PICKit 2,

this is available from suppliers world wide or direct from

Microchip.

Not got a programmer? Buy

a pre-programmed PIC from the On-line store

|

Description

|

Filename

|

Download link

|

|

Source code for 12F683

|

bdcm_remap108.zip

v1.0.8 22/07/2018

|

download download

|

|

HEX file ready to program into

the PIC

Standard version

|

bdcm_remap108_standard.HEX

v1.0.8 22/07/2018

|

download download

|

|

HEX file ready to program into

the PIC

Soft Start enabled version

|

bdcm_remap108_SoftStart.HEX

v1.0.8 22/07/2018

|

download download

|

Version

1.0.3 - Fixes a code bug which caused the two least significant bits of the

PWM

duty cycle value to be reversed.

Version

1.0.4 - Soft Start version

Version

1.0.5 - Fixed issue with duty cycle update causing noise at low settings

Added assembly time option to change internal Fosc

frequency which allows

different PWM periods/frequency to be used.

Set clock to 1Mhz for PWM frequency of (3.9Khz, 950Hz, 245Hz)

Set clock to 2Mhz for PWM frequency of (7.8Khz, 1.9Khz, 490Hz)

Set clock to 4Mhz for PWM frequency of (15.6Khz, 3.8Khz, 980Hz)

Set clock to 8Mhz for PWM frequency of (31.2Khz, 7.6Khz, 1.96Khz)

Added 8 byte rolling average filter to ADC input signal

Made common code base so there are no longer separate versions for standard

and Soft Start code. Options can be selected in the bdcm_remap_10x_common.asm

file prior to assembly.

Version

1.0.6 - Force 100% PWM output when duty value = 255. Because of

the way the PWM

peripheral hardware works within the PIC itself, setting the duty cycle register

to

255 actually only gets to 99.6% duty. This update forces it to 100% (always

on)

so it behaves as you would

expect.

Version 1.0.7 - Clear

PWM CCPR1L and DC1B1/DC1B0 bits of CCP1CON before enabling

PWM module since the value in the register is undefined after reset which can

cause a one cycle random output of the PWM at power-on.

Fixed

issue where changing the selected map would not register until the ADC duty

cycle input value changed. Now when a

new map is selected it forces an update of the PWM registers with the new map

values.

Version 1.0.8 - Fix

issue where PWM output doesn't restart after the RunStop input has been

activated until the input from the duty cycle potentiometer has changed

Soft start version

The Soft Start code features a soft

start at power up. If you imagine having the control

potentiometer set at zero and rotating it to its final position

each time the controller is powered on this is a soft start.

Instead of doing this manually, the control potentiometer can be

left in any position and the output is automatically 'ramped' up

to the current position of the control potentiometer each time

the controller is powered on.

If the control potentiometer is

at maximum it takes approximately 1.2 seconds for the output to

ramp up to the final setting, the time taken is directly

proportional to the position of the control position; for

example if the control is at 1/3 maximum it takes 1.2/3 = 0.4

seconds.

This code version is identical

to the original in respect to the operation of the modes and

lookup data tables for the remap functionality described

elsewhere on this project page.

This code will not work

with the PIC 12F629 or PIC12F675 since they do not

have the required internal CCP peripheral used to generate the

PWM signal.

|