|

|

Internal

Oscillator Recalibration Utility

for PIC 12F629 & 12F675

|

|

Description

The PIC 12F629 and

12F675 devices have an internal 4Mhz oscillator that enables the

devices to be used without an external crystal or RC network.

This frees up one or two pins for I/O use and allows the device to

be built into minimum component count designs.

The internal oscillator needs to be

calibrated and this is achieved by reading a factory programmed

calibration setting and writing it into the OSCCAL register during

initialisation of the device by the application software.

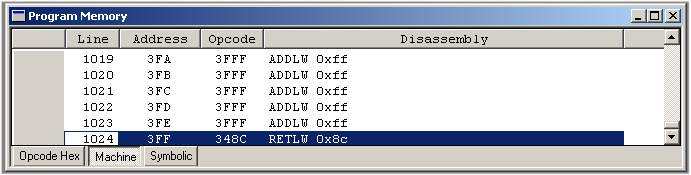

The calibration word is located at the

last address in the user program memory area, address 0x3FF.

It is in the form of a RETLW instruction and the user code should

include a CALL 0x3FF instruction which will return with the

calibration setting in the W register. This can then be written into

the OSSCAL register.

Problems arise if by accident or

otherwise, the program memory at address 0x3FF is erased or over

written. Since the calibration value is unique to each

individual PIC there is no way to know what it was, but it is

possible to recover it by recalibrating against a known frequency.

That's where this software and circuit

come into their own. Load a PIC with the code on this page and

drop it into the circuit described here and within a couple of

seconds it will provide a new calibration value to ensure the

internal oscillator runs within 1% of 4Mhz.

PICkit 2 update

If you have a PICkit 2 programmer, get

version 2.50 (or later) software from the Microchip

website. This includes a menu option to recalibrate and

reprogram the OSSCAL setting in one operation. This project

page remains here for those who don't have access to a PICkit2.

How it works

In order to calibrate

the internal oscillator a known reference frequency is needed.

Fortunately we don't need signal generators or calibrated test

equipment for this. In fact an accurate reference is available from

the AC utility electric supply. In most parts of the World the

utility electricity

supply is generated at a frequency of either 50 or 60Hz (many digital clocks take advantage of this fact to keep time)

Using almost any

transformer (or Wall Wart) with a 6 to 12 volt RMS AC output we can obtain an accurate

reference source to calibrate the PICs oscillator against.

Schematics,

Construction, and Code

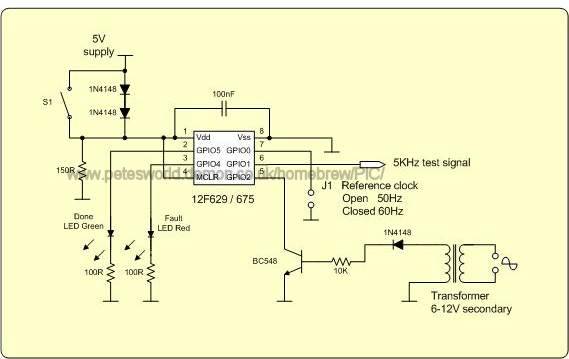

So let's get on with

it. Construct the circuit shown below using a piece of strip

or pad board, or just hook it up on a solderless breadboard.

The frequency of the

internal oscillator in the PIC varies with both changes in temperature

and supply voltage. As the supply voltage increases the frequency

decreases slightly. When switch S1 is open the 5 volt supply to

the PIC is dropped across the two diodes to about 3.4 volts. With

S1 closed, the PIC operates at 5 volts. Microchip calibrate parts

at 3.5 Volts / 25oC. With this circuit you have the

option to calibrate at either 3.4 volts or 5 volts. Unless you have

a specific reason not to, it is advisable to recalibrate the PIC

using the S1 open (3.4 volt) setting.

S1 open -

calibration takes place at 3.4 Volts

S1 closed - calibration takes place at 5 Volts

S1 is not a power on/off switch

S1 is not a power on/off switch

The two 1N4148 diodes

provide the voltage drop and the 150R resistor draws sufficient current

to ensure the voltage across the diodes remains stable.

The 100nF decoupling

capacitor should be placed as close as possible to the power pins (1 and

8) of the PIC.

The reference signal is

supplied using the BC548 transistor, 10K resistor, 1N4148 diode and

transformer. You can use any general purpose NPN transistor here

as it is not critical. The transformer is also not too critical

but should output between 6 and 12 volts AC RMS.

It is important that input

to the transistor is an AC signal. Don't use DC, not even unfiltered

DC (no smoothing capacitor)

DO NOT UNDER ANY

CIRCUMSTANCES CONNECT THIS CIRCUIT DIRECTLY TO THE UTILITY POWER DO NOT UNDER ANY

CIRCUMSTANCES CONNECT THIS CIRCUIT DIRECTLY TO THE UTILITY POWER

PIC code for recalibration

Next you need to

program the PIC to be recalibrated with the code below. The same code will work with

both the PIC 12F629 and 12F675 devices. Download it now and and program it into the PIC to be calibrated.

Download HEX code  (for use

with either 12F629 or 12F675) (for use

with either 12F629 or 12F675)

| Saved your day?

Rescued your PIC? Say thanks will a small donation

|

|

Once you have

successfully recalibrated the PIC and read back the new calibration

value you can reprogram the PIC with your own application code.

This software is only needed to calculate the new calibration value,

it doesn't need to remain in the PIC afterwards. (someone will ask

believe me!)

Running the calibration

-

Close J1 if the

utility power in your area is generated at 60Hz and leave it open if

it is 50Hz. Make sure you get this right or the calibration

will either fail or worse, be incorrect.

J1 Open - AC Utility Power Supply 50Hz

J1 Closed - AC Utility Power Supply 60Hz

-

The AC reference signal

should be present before powering up the PIC under calibration to ensure

the signal is stable and running.

-

Insert the PIC into the

socket, open switch S1 and apply 5 volts to the circuit.

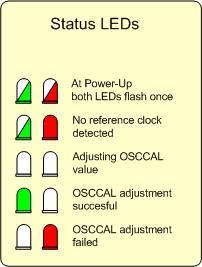

- When the PIC

starts both the LEDs will blink once.

- If no reference signal is detected

on GP2 (pin 5) the fault LED will light and the 'done' LED will

blink until a signal is detected. (If this happens, turn the

power to the PIC off and on to ensure it calibrates correctly)

- During the calibration process

both LEDs are off. The calibration will take less than 5

seconds to complete.

- If the calibration failed the

red LED will come on and the code will halt.

- If the calibration is

successful the green ' done' LED comes on and a 5Khz test signal

will be generated on GPIO1. If you have a frequency meter

handy you can use this to verify the calibration.

- Once calibration is complete,

you can open and close switch S1 while monitoring the 5KHz test

signal to see the change in frequency vs. supply voltage.

- Turn the power off, remove the PIC from the test circuit and

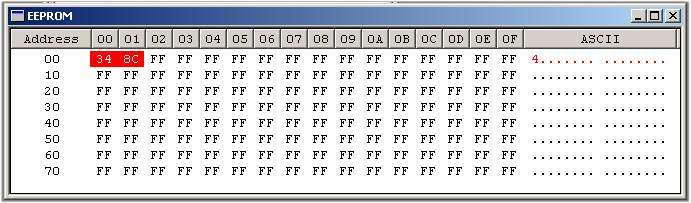

put it in your programmer. Now read back the PIC and

inspect the contents of the EEPROM memory

-

When you read back the

EEPROM it will contain one of three pairs of values in addresses

0x00 and 0x01 as follows:

EEPROM addresses

0x00 and 0x01 contain 0xFF

EEPROM addresses

0x00 and 0x01 contain 0xFF

then the code failed to run correctly.

EEPROM addresses

0x00 and 0x01 contain 0x00

EEPROM addresses

0x00 and 0x01 contain 0x00

then the code did run but it has failed

to set the calibration word correctly (finished with fault LED on).

Check that your reference clock is running at the correct frequency,

J1 is set correctly and then retry.

EEPROM address

0x00 contains 0x34 and address 0x01 contains 0xNN where NN is the

new calibration setting.

EEPROM address

0x00 contains 0x34 and address 0x01 contains 0xNN where NN is the

new calibration setting.

then the code ran successfully (finished with 'done'

LED on) and calibrated the OSCCAL value correctly.

Use the 0xNN value in address 0x01 for the calibration

memory.

|

|

Update:

It has been brought to my attention

that some programmers / software raise the VDD supply before VPP.

This allows the code to start running before the PIC enters

programming mode prior to reading back the EEPROM. If the

green LED indicates a successful calibration but on reading the

EEPROM back you find it contains 0xFF in addresses 0x00 and 0x01

then your programmer is doing this.

If you have this problem you can

download a modified version of the original program below.

This version doesn't initialise the EEPROM on startup so the

calibration data doesn't get cleared when the PIC is read back in

the programmer. Only use it if you have this problem.

Download HEX code  (modified

version with no EEPROM initalisation) (modified

version with no EEPROM initalisation)

Using the new

calibration word

-

IMPORTANT: This code

will calculate the correct calibration word but it can't

save it back into the PICs program memory - You must do this

manually using your PIC programmer.

-

If you

calibrate a PIC where you still know the factory calibration

value you may find the value produced by this circuit is

slightly different from the original factory value.

This is normal and is down to differences in supply voltage

and temperature. You can verify the 5Khz test

signal on GP1 with a frequency meter after calibration is

complete and it should be within 1% of 5Khz.

|

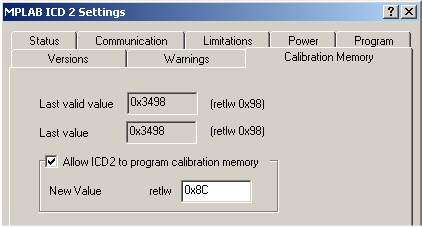

If calibration

completes successfully, remove the PIC and place it back into your

programmer. Read back the data from the PICs EEPROM memory

(not program memory) where the newly calculated value has been

saved. (see example below)

Address 0x00 will

contain 0x34 and address 0x01 will contain the calibration value.

It is this value that needs to be written back to program memory

location 0x3FF using a RETLW instruction. Some

programmer software will allow you to enter the calibration value

and program it back into the device for you. If your

programmer doesn't do this then you need to put a RETLW 0xNN

instruction at address 0x3FF where 'NN' is the hex calibration value

read from the EEPROM.

Contact us:

|