|

|

Scalextric Sport

Race Start Controller

with jump start detection

From

this page

|

|

Overview

I developed this after my nephews got a

Scalextric Sport slot car racing set for Christmas. The set included

a lap timer and counter but one thing that was missing was a way to start

a race. Having someone say "3-2-1-Go" wasn't really doing

the job, especially as it was easy to go just after "1"

and before "Go" This works in a similar way to the lights

used in F1 motor racing with five lights illuminating sequentially,

holding for a random time before all lights turn off to signal the race

start.

I put together a battery operated version

one afternoon between Christmas and New Year, it took about four hours

from concept to completed hardware in a box. [see

original] It worked quite well but we still had the issue of 'jump

starting' so I decided to develop things further.

I had four key requirements for the design.

- It should work with the standard

Scalextric power-base (part C8217), throttles and transformer pack.

- It had to be simple to use.

- Powered from the Scalextric power

supply, no extra transformers or batteries.

- Not require any alterations to the

Scalextric power-base, throttles or cars.

I know that there's a lot of computerised

solutions that will do all kinds of smart things out there, including

controlling the start of a race, but not everyone wants or needs that

level of complexity. The device described on this page is easy to

use, cheap to build and doesn't require any permanent modifications to the

original Scalextric setup, although it can be hard wired in to permanent

setup should you wish to do so.

Using the controller is very simple. To start a race simply press the start

button. The controller than waits for both hand throttles to be

released before starting the countdown. During the countdown the

LEDs illuminate at 1 second intervals until all five LEDs are on.

The start of race is signaled when the LEDs extinguish after a random

delay of between 0 and 3.5 seconds.

The start controller detects a jump start

by sensing the hand throttle; if it's operated during the countdown the

controller will either ignore it, display a Jump-Start condition on the

LEDs after the countdown completes, or abort the countdown and display

Jump-Start condition on the LEDs. This action is determined by the

operating mode which is user configured.

Operation

and modes

-

Mode 1 - Turn

track power off during start sequence, restore power at 'Go' signal.

-

Mode 2 -

Normal start countdown, no jump start detect.

-

Mode 3 - If

jump start detected during countdown, track power is cut, start

sequence aborts and jump start condition is displayed on LEDs..

-

Mode 4 - If

jump start detected during countdown, start sequence continues and

then one

second after 'Go' signal Jump start condition is displayed on the LEDs.

Graphical representation of the four

modes are shown in the PDF document here.

If the Controller is used on its own

without the PSU described here then modes 1

and 2 behave in the same way. Reference to the track power is also only

relevant when used with this PSU. The Controller still functions in

all other respects as described.

Start Race

To start a race countdown, press and

release the start button. LEDs 2 and 4 light if the controller has

detected an open throttle. Countdown commences when both throttles are

released.

Change Modes

To change modes, press and hold the start

button for 3 seconds. When the controller goes to mode change setup a

single LED will light indicating the current operating mode.

Repeatedly pressing the start button will cycle through the four modes.

When the desired mode is selected press and hold the start button for 3

seconds until the LED turns off.

Operating modes can be changed at anytime,

except when a start is in progress. The

mode is saved to non-volatile memory so the controller will start up in

the mode that was selected when it was last used.

Construction

Full details of the Race Start Controller

with schematics and PCB layouts are provided below. Click

on the images for full size view.

|

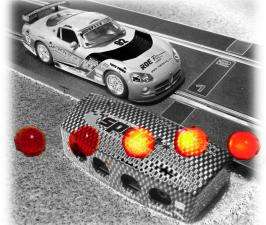

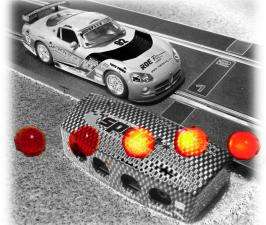

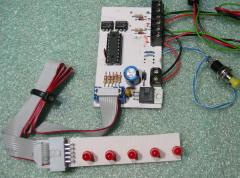

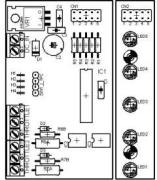

Photo of the start

controller connected to a standard Scalextric Sport powerbase and

throttle. |

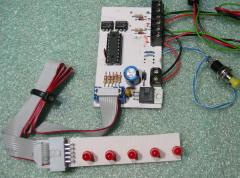

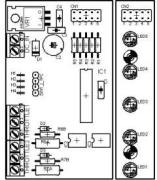

Close up of the start controller

PCB. I've used PCB mounted screw terminal blocks for the connections to the

throttle wiring, power and an IDC header for the LED board. There is no

reason why the wiring can't be made directly to the PCB saving the cost of the

connectors. |

Inside a standard 45ohm Scalextric

Sport hand throttle. The inset diagram shows how the throttle is wired.

When the throttle is in the closed position (as shown in the photo) the wiper

(black wire) short circuits to the 'brake' contact (red wire). It is this feature that is

used to detect jump-starts. |

|

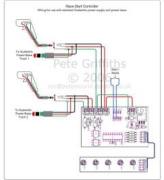

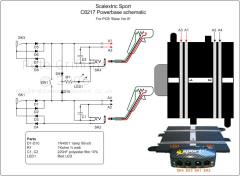

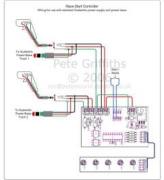

| The

wiring and circuit schematics show how to connect the Race Start

Controller to your Scalextric Sport powerbase track and hand throttles.

If you're building this I assume

you have some knowledge of electronics and circuit construction. The electronic side of the circuit

operation is fairly self explanatory.

|

Wiring Schematic

click here for PDF version

|

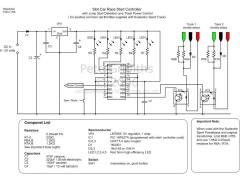

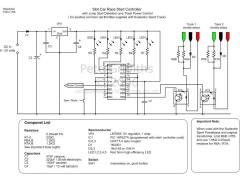

Race Start Controller Schematic

click here for PDF version

|

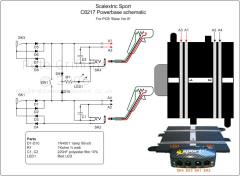

| A schematic

diagram of the internals of the Sport Powerbase track part

C8217.

You can see from this that

the power delivered to the car is unsmoothed DC. D1/C2 on the controller PCB isolate and smooth this

supply which is then fed into voltage regulator VR1 to get a 5

volt output for the controller. |

|

|

| |

PDF version |

|

A few facts, traps and other information

to be aware off during construction and testing.

-

As detailed

on the circuit schematic, you must use 1.8Kohm resistors for R6A and

R7A and omit R6B and R7B.

-

I recommend

powering up the circuit without the PIC installed and using a

voltmeter to check that you have something between 4.8 and 5.1 volts

between pins 5 and 14 of the IC socket. If not correct the

problem before inserting the PIC.

-

The

standard Scalextric Sport Power base transformer pack outputs 16V RMS

under full load. Without a load (that is when the cars are stationary)

the peak output can be almost 27 volts. Therefore the 220uF capacitor, C2 on the schematic, which is

shown rated at 35 volts should not be substituted for a 25 or 16 volt

alternative.

-

The jump

start detection works by sensing when the throttle wiper is contacting

the brake connection. Some throttles are more sensitive than others

where this is concerned. If the controller continually shows a

throttle open status when you press the start button, check that both

throttles are connecting the wiper to the brake contact in the

throttle.

-

Be careful

when wiring the 3.5mm jack plugs that the wires and connectors don't

short together when you slide the cover on. Ideally use some sleeving

over the soldered connections.

-

The wire

colours shown are those I've found in a number of Scalextric Sport

hand throttles and I've used those in the schematics for ease of

reference. I don't suppose they'll change it, but it's

always worth checking.

-

The

Scalextric Sport Powerbase allows either a single transformer to be

used or separate transformers for each track. The start

controller will work with either configuration without modification.

-

The start

controller circuit uses ~75mA with all five LEDs illuminated and under

5mA with all LEDs off. Each throttle sense opto-coupler will

draw around 10mA continually.

-

The

throttle sense circuit works by using the lower forward voltage drop

of a normal diode to 'by-pass' the LED in the opto-coupler when the

throttle wiper connects to the 'brake' terminal. This also means

that when no throttle is connected, it appears to the controller that

the throttle is closed so the circuit can be used with only one

throttle

-

The

throttle detect circuit works with a common positive brake

connection. The throttle wiper varies the negative supply to the

track. It's not how I would have designed it myself, but that's how

Scalextric have done it so that's what it has to work with and to be

fair it doesn't really make any difference.

-

When I got

into building this I bought another Powerbase track section and four

sets of hand throttles to pull apart, test and play about with.

The circuit has been used with my test track, the original track the

kids got for Christmas and with six different Scalextric hand

throttles. I've not had any problems, but if you do I'd be interested

to know more - drop me an email.

Testing

Once the circuit is constructed,

connect to the Powerbase as shown in the wiring schematic

above. It's not necessary to have any cars on the track while

you're testing the controller.

When power is first applied, the LEDs

illuminate in a sweeping pattern to indicate it has powered on okay.

- If you now hold open one of the

throttles and then press the start button you should see LEDs 2

and 4 illuminate.

- Release the throttle and LED 1

should light followed by LEDs 2 to 5 at 1 second

intervals.

- When all five LEDs are on they

will turn off after a random delay of 0 to 3.5 seconds.

- Repeat steps 1 to 3 with the

other hand throttle.

If it has worked as described, the

circuit is functioning correctly.

|

|

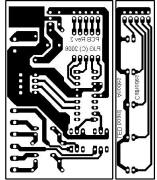

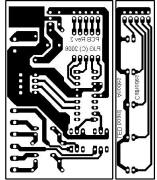

PCB Artwork

The Controller PCB and

LED PCB are done as one layout. You can either cut the artwork and

etch the boards separately or etch the board as one and cut the PCB

afterwards which is how I do it.

If you're not able to

make your own PCB here's a prototype pad board layout. You should be

able to work out from the schematic what the components are. The

layout is similar to the PCB and the connections at the edge are the

same as those on the PCB so the wiring schematics can still be

followed.

|

PCB Layout (PDF)

Component Overlay

(PDF)

|

|

Alternate

PCB and component kit for this project.

You can now buy a PCB and kit of parts

for this project. It uses an alternate PCB design to that

shown above.

An an additional project page has

been added with full construction details. The assembled board

can be substituted for the one shown on the main page here

See kit #484 supplemental project page |

|

Parts

Listing

You can buy all the parts

needed to build this project from most component suppliers world

wide. In the UK you can get everything from Rapid Online and

I've included a parts list with their part numbers below.

-

All

Rapid parts/descriptions correct at 19-Sept-2008. You should

check part# and descriptions are correct when ordering in case

I've made a mistake transferring them onto this page.

-

The

resistors are sold by Rapid in packs of 100 and the ribbon cable is a 30M reel. You may find it

cheaper to buy some or all of the parts from other sources - I make no

recommendation.

-

You will also needs some short

lengths of wire for the interconnections between the PCB and the jack plug

and sockets. Rapid sell a pack of 11 colours x 2M lengths of stranded

equipment wire, Part # 01-0108

| Qty |

Part Number |

Description |

| 2 |

20-0125 |

3.5mm stereo jack |

| 2 |

20-0155 |

3.5mm stereo socket |

| 1 |

78-0040 |

Green push button switch |

| 1 |

47-3130 |

1N4001 diode |

| 2 |

47-3308 |

1N4148 diode |

| 1 |

47-3313 |

7805 5volt regulator |

| 2 |

58-0826 |

CNY17-4 opto-coupler |

| 5 |

55-0155 or 55-0117 |

5mm bright red LED

or standard red LED |

| 1 |

73-3384

(needs programming see

below ) |

Microchip PIC 16F627A |

| 5 (sold in packs of 100,

order Qty 1) |

62-0354 |

220 ohm 0.25 watt resistor |

| 2 (sold in packs of 100,

order Qty 1) |

62-0376 |

1.8K ohm 0.25 watt

resistor |

| 1 |

11-1022 |

10uF / 16volt Tantalum

Capacitor |

| 1 |

08-0237 |

47nF disc ceramic

capacitor |

| 1 |

08-0235 |

100nF disc ceramic

capacitor |

| 1 |

11-0355 |

220uF / 35v electrolytic

capacitor |

| 1 |

21-1810 |

2-way, 16A interlocking

terminal |

| 2 |

21-1812 |

3-way, 16A interlocking

terminal |

| 2 |

19-0500 |

10-way box header |

| 2 |

19-0300 |

10-way cable mount socket |

| 1 |

01-0167 |

10-way ribbon cable 30M

reel |

| 1 |

22-0165 |

18 pin DIL IC socket (for

16F627A) |

PIC

Firmware

The Microchip PIC 16F627A

requires programming with the firmware for the start controller.

The HEX file ready to

program into a 16F627A can be downloaded for free from

here

(right-click Save As). (right-click Save As).

(a 16F628A can also be used without any modification to the code or

hardware)

If you have problems programming the HEX file into the PIC make sure you

are using Vpp first programming mode. For PICkit2 programmers you

can find this option under Tools - Use VPP First Program Entry

If you have problems programming the HEX file into the PIC make sure you

are using Vpp first programming mode. For PICkit2 programmers you

can find this option under Tools - Use VPP First Program Entry

This code works with the

hardware design shown on this page only. For the code used with

the Race Start Controller kit #484 please see the

supplemental project page This code works with the

hardware design shown on this page only. For the code used with

the Race Start Controller kit #484 please see the

supplemental project page

Use

with other slot-car systems

Not having experience with

other makes of slot-cars I can only say it works with Scalextric, though I

expect it would work with other makes that use a three wire throttle.

If you want to use the circuit

with other throttle systems the following information will help.

The throttle detect works as

follows. The PIC port pins RB4 and RB5 detect throttle 1 and throttle

2 respectively. A high logic level on either pin signals to the PIC

firmware that the respective throttle trigger is released (closed) and a low

logic level signals the throttle is open (trigger moved). The

'weak internal pull-up' feature is enabled on the PIC so no external pull-up

resistors are needed on these inputs.

Resistors R6A and R7A set the

current through the LEDs in the opto-couplers. Ideally for a given

input voltage the peak LED current should not exceed 50mA and the average

current ought to be around 10-15mA. When the throttle triggers are

released the resistors are dropping Vin-0.6 volts, the drop across the

1N4148 diode. This is the highest dissipation condition and you need

to make sure that the power dissipation in the resistors does not exceeded

their maximum rating.

The PCB layout was

specifically designed to take two resistors in parallel which allows

standard 0.25 watt resistors to be used where the power dissipation in one

resistor alone would exceed 250mW.

You also need to consider that

with transformer packs like that supplied with the Scalextric the off-load

output voltage is higher than the voltage stated.

For example. With the 16

volt AC / 800mA transformer pack supplied with the Scalextrix I measured an

offload RMS output of 19 volts (peak 26.8 volts). Fully loaded the RMS

output of 16 volts has a peak of 22.5 volts.

Dual

Output PSU

You may have noticed on the

controller schematic a 'Power Control' signal from RB0 pin of the PIC.

I've also designed and built a dual output variable voltage power supply for

my Scalextric setup. This features a power shutdown input which, when used

with the race controller described above, shuts off the power to the track

when a jump start is detected. It also has a 'launch control' start mode

where power is cut to the track during the start countdown and then restored

when the LEDs go out.

See

full PSU project here

Development rig

|