|

Power LED

Strobe

for PIC12F629 / 675

|

|

Description

|

This project functions as a

simple strobe for driving a high power type LED. The output

driver provides current limiting suitable for use with either

350mA / 1 Watt LEDs or 700mA / 3 Watt LEDs.

Output from these LEDs is

extremely bright and visible from a considerable distance, even

in daylight.

Four jumpers provide options

for changing the pulse width, strobe repeat interval and single or double

strobe flash. There is also a Strobe Inhibit input that

can be used to stop the strobe pulse using a switch. The programmer ready code has default

timings which are easily customised by editing values in the PIC's EEPROM at programming time. |

|

|

Warning.

The light output from Power LEDs is very intense. Avoid

looking directly at the LED when operating. |

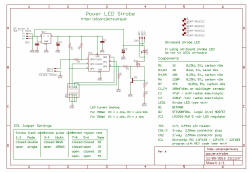

Schematic

Download

schematic in PDF

Circuit Description

The circuit provides a LED

strobe function with jumper selectable operating modes.

Firmware running in the PIC microcontroller produces precise

control of the strobe output pulse while an inhibit input allows

an external signal or switch to inhibit operation.

The strobe interval can be

configured using 4 jumpers for 1,2,3 or 4 seconds; strobe on time of 30mS or

100mS and single or double strobe pulse. Timings are

stored in the PICs EERPOM and can be customised as needed.

High power LEDs ideally need

driving with a current source to maintain a constant fixed current through the

LED. In this application I've used a simple linear current

limiter around Q1 and Q2. Since the LED is driven with

very short pulses and relatively long intervals between them the

average power dissipation is very low and neither the LED

or the output MOSFET require heatsinks.

Resistors R2+R3 set the current

limit. With R2 = 1 ohm and a wire link for R3, current is

set to 700mA. Using a 1 ohm resistor for both R2 and R3

(for a total of 2 ohms) sets the limit to 350mA.

LED1 connects between the

positive supply and the drain of

logic-level MOSFET Q2. The source of Q2 connects to

ground via R2+R3. When Q2 turns on the current passing

through the resistors R2+R3 causes a voltage drop to appear

across them. (Ohms law V= I x R ). The base of Q1 is

connected across the resistors and when the voltage reaches

about 0.7 volts, Q1 begins to turn on. The

collector of Q1 is connected to the gate of Q2 so so as it turns

on it pulls the voltage on the gate of Q2 towards ground, which

starts to turn Q2 off. This settles at a point where a

constant current is passed through R2/R3.

The strobe LED can either be

installed on the PCB in position LED1 or off-board via connector

CN3. If the off-board option is used do not install a LED

into position LED1 on the PCB.

Capacitor C1 is used to

decouple the 5 volt power supply rail. If you are building the

circuit on a breadboard or stripboard you should ensure it is

located close to the PICs Vdd connection (pin 1).

Capacitor C2 and C4 are

required by the LDO voltage regulator to stabilise its output.

The original design uses an LM2931-5.0 LDO regulator designed

for automotive applications. It can withstand reverse

polarity connection and 60 volt spikes at the input. You

can substitute other LDO regulators or a 78L05. If you use

a 78L05, minimum input voltage needs to be 7.5 volts.

The input voltage should be

between 5.5 and 9 volts smoothed DC. The power supply

needs to be able to supply in excess of 700mA, so a supply rated

at 1 amp or greater is ideal. You can use batteries to

power the circuit but they will need to be able to supply the

high currents required by the LED. The 7.2 volt

rechargeable battery packs used with RC models would be ideal

for this.

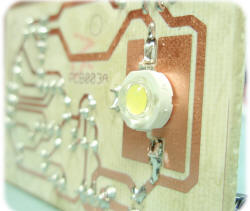

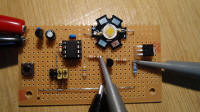

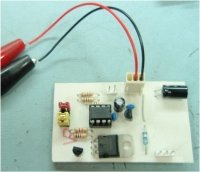

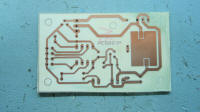

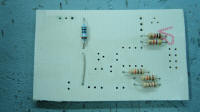

photos above show

development of the power LED strobe

Strobe inhibit control

The GPIO5 input to the PIC

functions as a Strobe Inhibit. When the input is held low,

the strobe output is inhibited. If you don't need this

feature, you can omit resistors R5 and R6 and leave the pin

disconnected as it has internal weak-pull enabled.

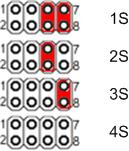

Mode Jumpers

The Strobe operating modes are

selected by using jumper block JP1. If you are building

the strobe for a specific application you may want to hardwire

inputs to ground as required rather than fit the jumper pin

header.

LED1 Options

The design will work with

either 350mA or 700mA LEDs. If a 350mA LED is used,

populate R2/R3 with 1 ohm, 0.25 watt, 1% resistors. If a

700mA LED is used, substitute a wire-link for one of the

resistors and use a single 1 ohm, 0.6 watt 1% resistor for the

other.

We avoid the need for heatsinks

on the LED and output MOSFET by using a very short duty cycle.

It is important not to allow the LED to remain on continuously

either through a fault or by modifying the pulse

width/repetition rate

You can drive up to three LEDs

in series using CN3 to make the external connection. The

power supply input voltage needs to be greater than the sum of

the forward voltages of the LEDs + 1 volts

For example: If you are

using two white LEDs with a forward voltage of 3.6 volts, the

power supply input voltage should be: 2 x 3.6 volts + 1 volt =

8.2 volts. In this case a 9 volt power supply would be

ideal. For three LEDs in series use a 12 volt power

supply.

MOSFET Types

This circuit is designed around

a logic-level MOSFET for Q2 which has a gate threshold voltage

of around 2.5 volts. You may find standard, non logic

level MOSFETs with higher gate threshold voltages can't turn on

sufficiently to provide 700mA of current to the LED.

Although the LED will be on and may appear very bright, it won't

be operating at the desired 700mA current.

I've tested this circuit with

STP36NF06L, STP20NF06L and NTD5867NL. The NTD5867NL

comes in IPAK-369D through-hole and DPAK smd package types so

doesn't fit the PCB layout but is ideal if you want to do your

own compact design.

Strobe Operating Modes

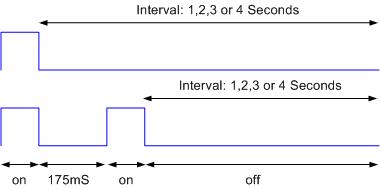

This section refers to the

default timings used in the programmer ready firmware download.

The pulse width, interval and

strobe mode are user selectable using the JP1 jumper block.

There are two strobe modes, single and double pulse. The

double mode has a (default) 175mS off-time between the two pulses.

As shown in the diagram below, the interval is measured from the

end of one pulse group to the start of the next group.

Default timing

Jumper Settings

|

Strobe

Mode

JP1 (1-2)

|

Pulse

Width

JP1 (3-4)

|

Interval

JP1 (5-6,7-8)

|

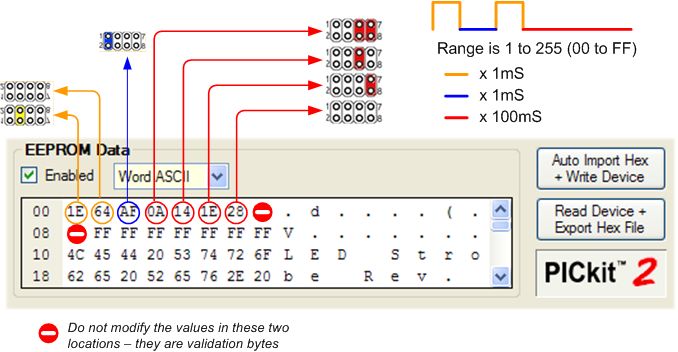

Customising the strobe

timing

The timers for the pulse width,

interval and double mode gap are all configurable by editing the

values in the PICs EEPROM before writing the HEX into the PIC.

This is nice and easy to do and doesn't require reassembling the

code or anything complicated. Just load the HEX file from

the firmware download section into your programmer application.

Edit the values in the EEPROM as shown below and then write the

code and EEPROM data into the PIC.

Suppose you want a pulse width

of 40mS (40 x 1mS) and an interval of 1.3 Seconds (13 x 100mS) you would

set

the data in address 00 to 28 (40 decimal == 28

hexadecimal). For the 1.3 second interval change the data

in address 03 to 0D (13 decimal == 0D hexadecimal).

Values shown in the example

above are the default values in the firmware download. If

you don't modify them it will uses these timings.

Converting decimal values to

hexadecimal

Depending on your programmer

the values you need to enter will probably be in hexadecimal, easiest way to

convert decimal values to hexadecimal is Google, see example

below. The prefix 0x in the result simply tells us the

value is in hexadecimal (hex for short).

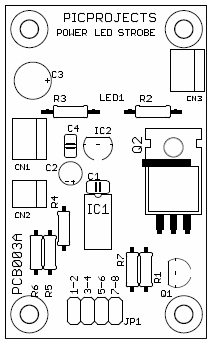

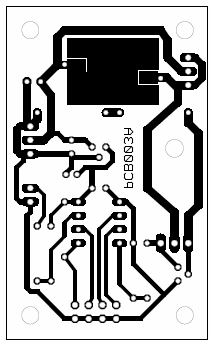

PCB Layout

Download PCB

artwork in PDF

Download PCB

overlay in PDF

Component List

You can buy all the parts

needed to build this project from most component suppliers world

wide. In the UK you can get everything from Rapid Online and

I've included a parts list with their part numbers below.

All

Rapid parts/descriptions correct at 11 September 2013. You should

check part# and descriptions are correct when ordering in case

I've made a mistake transferring them onto this page.

|

Component |

Description |

Part # |

| R1 |

1k Cr25 0.25w Cf

Resistor - Pack of 100 |

62-0370

|

| R2,R3

* |

1r 1% 1w Metal Film

Resistor (each) |

62-7890 |

| R4,R5

|

10k Cr25 0.25w Cf

Resistor - Pack of 100 |

62-0394

|

| R6 |

120r Cr25 0.25w Cf

Resistor - Pack of 100 |

62-0348 |

| R7 |

47k Cr25 0.25w Cf

Resistor - Pack of 100 |

62-0410 |

| C1,C4 |

100nf 2.5mm Y5v

Dielect Ceramic Capacitor |

08-0270 |

| C2 |

47uf 16v Radial

Electrolytic Capacitor |

11-3726 |

| C3 |

220uf 16v Radial

Electrolytic Capacitor |

11-3702 |

| Q1 |

BC548B TRANSISTOR TO92

30V NPN (RC) |

81-0066 |

| Q2

** |

Stp36nf06l Mosfet

Logic N 60v 30a |

47-0552 |

| IC1

** |

PIC12F629-I/P (RC) |

73-3262 |

| IC2

* |

Lp2950cz-5 Micropower

Regulator. |

82-0680 |

| LED1 |

w 3.3v White Power LED

200lm |

55-2003 |

| socket for IC1 |

8 Pin 0.3in Turned Pin

Socket |

22-1720 |

| JP1 |

4+4 WAY DOUBLE ROW

HEADER PLUG RC |

22-0555

|

| CN1, CN3 |

3 Way

2.54mm KK Molex Straight Header |

22-0840 |

| CN2 |

2 Way

2.54mm KK Molex Straight Header) |

22-0838 |

| order 4

|

OPEN BLUE 2.54MM

JUMPER LINK (RC) |

22-3555

|

| |

|

|

Parts List Notes

*

Rapidonline don't supply some

parts I used so I've specified alternative parts which should

work.

**

Alternate MOSFETs are STP20NF06L,

NTD5867NL

***

The PIC12F629 will need

programming with the firmware at the bottom of this page.

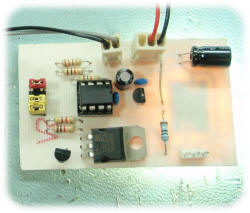

Construction photos:

Construction is very

straightforward. Fit the components in the order shown in

photos Fig 1 to Fig 6.

Fig 3. The two

electrolytic capacitors must be installed the correct way round.

The negative terminal is normally the shorter lead, it is also

marked on the side of part.

Fig 6. When you get the board assembled up to figure 6, connect

power to the board and check the voltage between pins 1 and 8 of

the IC1 socket. It should measure 4.9 to 5.1 volts, if it

doesn't don't continue until you have found out why and

rectified the fault.

Pin header C2 is only used if

you want to connect an external inhibit switch.

Pin header C3 is only used if

you want to connect an external LED. If you are using an

external LED, don't connect the on-board LED as well. It's

either on-board or external, not both.

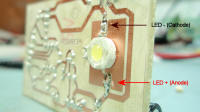

Fig 7. The power LED is

soldered to the copper side of the PCB. Make sure to

connect the anode and cathode terminals the correct way round.

Fig 8.

Avoid looking

directly at the LED when testing and operating the board.

The intense light output may damage your eyes. Avoid looking

directly at the LED when testing and operating the board.

The intense light output may damage your eyes.

Fig 9. Fully assembled

board with power connected to CN1 and a magnetic reed switch

connected to CN2 strobe inhibit input.

Fig.1 |

Fig .2 |

Fig. 3 |

Fig.4 |

Fig.5 |

Fig.6 |

Fig.7 |

Fig.8 |

Fig.9 |

Power Supply

The LED Strobe circuit ideally

needs a DC power supply in the range 5.5 to 9 volts and rated

for 1 amp or more. With the LDO regulator specified you could use 4 x 1.5V AA

high capacity Alkaline batteries (Not NiMH rechargeable as 4.8

volts output is insufficient to operate correctly)

If you want to use rechargeable batteries the 7.2 volt battery

packs used with Radio Controlled models would be ideal.

Firmware

You can use either a PIC 12F629

or 12F675 microcontroller with this circuit. The same

firmware code is used with either device. Download

the files required below.

The HEX file is ready to

program straight into the PIC. The asm file is the

source code which you can modify or just view to see how it

works.

Not got a programmer? Buy

a pre-programmed PIC from the

On-line store

|

Description |

Filename |

Download link |

| Source

code for 12F629/675 |

ledstrobe-PWR.asm |

download

download |

HEX file

ready to program into the PIC

for use with 12F629 & 12F675 |

ledstrobe-PWR.HEX V1.0.0 09/09/2013 |

download

download |

If you need a PIC Programmer I

strongly recommend the

Microchip PICKit 2,

this is available from suppliers world wide or direct from

Microchip. It's reasonably cheap to buy and reliable.

Troubleshooting

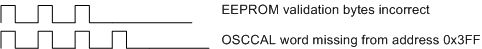

If the LED outputs blink 3 or 4

times at regular intervals and the jumper settings are

ineffective this indicates one of two fault conditions.

- The EEPROM data at addresses 07

and 08 must be 0xA9 and 0x56 respectively. If this is not

correct the 3 blink error code will be shown. You can

correct the error by reprogramming the EEPROM ensuring these

validation bytes are correct.

- If the OSCCAL calibration word is

missing the 4 blink error code will be shown. You will

need to recalibrate the PIC using a PICkit2 programmer, or the

recalibration project here

Contact us:

|