|

|

Serial

Controlled

RGB LED PWM

Driver

12F6xx based PWM

controller for RGB LEDs

|

|

Description

If you want to build your own multiple

RGB LED display that you can control from either a PC or a dedicated

controller then this project will let you do just that.

The project on this page came about

when while I was developing a more complex intelligent

driver. During that work I put together a simple Red/Green/Blue Pulse

Width Modulation LED driver that has a serial

interface. The RGB values to control the LED brightness are sent

to the PWM driver over this serial interface.

With both the original and revised

versions of the RGB PWM driver there was one big shortcoming when you

want to have several drivers working together. Even when they're

running the same sequence, the small differences in the frequency of the

internal RC oscillator cause some to run the sequence slightly faster,

others slower. The result, well sometimes it's quite effective,

but mostly it just looks awful.

With the controller / driver presented

here it is possible to connect multiple drivers to the same serial

cable, all attached units then appear to operate synchronously since

they're all receiving the same control data. The PCB for the RGB PWM Driver has been designed so

that it can be used with both the serial control firmware on this page,

or the standalone firmware here

The serial data can be sent from the

serial COM port of a PC or using a small dedicated controller that I've

put together. The Controller code is based on the standalone RGB driver

code described elsewhere on this

website. The controller uses the same format for the sequence data as the

standalone RGB driver so any SequenceData.inc files you have for the standalone

driver can be used with the Serial RGB Controller.

The pictures below show an RGB Driver

placed inside a 6" opal glass light fitting. I bought this from a

DIY store for £4.99 (see

here). When the LED driver is fitted in the base it

illuminates the whole globe. Because most 5mm LEDs have quite a

narrow viewing angle you tend to got 'hot spots' in the top but overall

it's very effective and makes for great mood lighting. (In

case it isn't obvious you do not connect the light fitting to the mains

electricity supply when used with the RGB Driver!!!)

Also check this mood light by Pete Rus

which is based on the Standalone PIC controller

http://www.instructables.com/id/E5A6O59KDPEUSZO1BK/?ALLSTEPS

How it works

Back to the RGB LED Driver.

Depending on which firmware you program into the PIC this PCB and

hardware can

operate as either a serial controlled driver or a stand-alone driver (see

here).

Serial Data Format

Serial Data is sent to the RGB PWM Driver

using a standard 2400bps asynchronous serial data stream (like you get

from the COM port of a PC). The serial frame

format is 1 start bit, 8 data bits, 1 stop bit. RS232

devices, including the PC COM port, always generate a start bit so when

you look at the serial port parameters in Windows you won't see it as an

option. Use 8N1 for the COM port settings.

The RGB values for the PWM

driver are sent in a five frame packet.

- The first frame must always

contain the value 0x81 (129 decimal)

- The next three frames contain the

8-bit Red, Green and Blue data for the PWM driver.

- The last frame is the checksum.

It should contain the 2's compliment of the sum of the previous four

frames, modulo 256.

The code snippet below shows the checksum computation in PIC

assembler.

movlw

0x81

addfw

RedPWM, W

addfw

GreenPWM, W

addfw

BluePWM, W

sublw

0x00

movwf

chksum

The Serial RGB Controller will take care

of all this for you. However, if you write an application to generate

the data from a PC the application itself will need to take care of

this.

Controlling from a PC

During development of the Driver I put

together a couple of short Perl scripts for testing purposes. The first

one takes user entered RGB

values and sends them through the PC serial port to the driver.

The second one sends a continuous stream of RGB data to the driver that

generates a 'wave' effect. (Both scripts are hard coded to use

COM1)

At this point I need to make it clear I

am not supporting the Perl scripts. The ability to send data to

the Driver from a PC is a bonus. If you don't know Perl or have no

previous programming experience you will probably be unable to make use

of them.

PLEASE DO NOT e-mail me asking for help with these scripts

I don't like having to say that, but PIC programming I do for fun;

Perl I do not.

The scripts are written for ActivePerl

and require the module Win32::SerialPort.

Some Perl resources - if you want to learn Perl.

If you

write some code for the PC to control the driver boards and you're

prepared to share it, let me know and I'll be happy to link to it from here.

Addressable version of the Serial

controlled RGB PWM driver (added January 2011)

IMPORTANT: Please be absolutely

clear about this: it's available, it's free, it does work and has been

tested but I will not support it, modify it, or help you implement any

application with it. Please don't email me asking for any support -

really.

The project on this webpage is a based

on code I wrote for an addressable RGB controller, it's just a cut down

version. At the time I wrote it I didn't have any supporting

software to send data to the addressable modules, for that reason I

didn't make the addressable code available. I still don't have any

code other than that I used for my own application. I actually

went on to develop the the Serial Addressable RGB PWM

LED/Servo Driver which was much better, if a bit more complex.

However over the last four years I've

been contacted by email on many occasions asking for an addressable

version of this project and I've let people have the code I'm now making

available here on request.

The packet format is described in

detail in the PDF file download:

Packet format

The source code for the addressable

version of the Serial controlled RGB PWM driver can be download

from here

Operation

There are two parts to this

project.

Sends RGB data to the

drivers over a serial interface.

|

|

- Serial RGB LED PWM Driver

Drives RGB LEDs using Pulse

Width Modulation (PWM) at an intensity controlled by the

most recent serial data packet received by the driver.

The

data can be provided by the Serial RGB Controller or from

the COM port (RS232 interface) of a PC.

|

|

Serial RGB Controller

- When the Serial RGB Controller is first powered on after

programming, it should start running the first RGB sequence found. If

you're using the original sequences supplied with the code it will

run a sequence of red-fade out, green-fade out, blue-fade out

repeatedly.

- Press the SW1 sequence select switch to

step through all available sequences. When the last sequence has been

reached it will go back to the first available sequence. Each time

the SW1 switch is pressed the RGB LED PWM values are set back to 0 (LEDs

off)

- About 10 seconds after the SW1 sequence

switch is last pressed the currently selected sequence number is saved to

non-volatile EEPROM memory. When the Serial Controller is next

powered on, the saved sequence number is read back and will automatically start

running.

Serial RGB LED PWM Driver

- Operation of the Driver is very

straightforward. You send it correctly formatted and

checksum'd packets through its serial interface. It will then

drive the RGB LEDs with those values until it receives another

packet.

- If you're driving it from a PC,

avoid sending a continuous stream of packets back-to-back when the

RGB values have not changed; it serves no useful purpose and causes

the LED's to vary slightly in brightness due to the demands on the

software in processing the serial data stream.

- After power-up the LED's are

turned off and will remain off until it receives valid RGB data over

the serial interface

Code, Construction & PCBs

|

Serial RGB

Controller |

Serial RGB LED

PWM Driver |

|

Note: These photo's show

the original PCB layout under construction. I've since

done a second revision to the PCB which is provided in the

files above.

|

The PCB can be used

with both the Stand-alone firmware and the Serial Controlled

Driver firmware.

- If you build the

stand-alone version you can omit Q1, R1 & R2

as shown in the picture above right.

- The Red Green & Blue

LED's are not specified because I expect you will source

these yourself depending on what you want / have / can

afford etc. Therefore you will also need to

calculate the correct series current limiting resistor

required to use with the specific LEDs used.

LED Resistor calculator

- Jumper J1 is not used

on the Serial RGB LED PWM Driver - leave it open.

- Capacitor C3 is

specified as optional. I've never used it and I've never

had any issues. If you check the datasheet for the

78L05 it is recommended if the power supply is more then

75mm (3") from the regulator so I've made provision for

it on the PCB.

-

Construction tip:

When you solder the LED's to the PCB, only solder

one lead of each LED. Once all the LED's are

fitted, you can move the LEDs around to get them all

neatly aligned. Once you have them aligned, solder

the remaining lead on each LED. If you try moving

them once both leads are soldered you risk ripping the

copper off the PCB.

|

|

|

|

ESD and MOSFETs

Please read this |

|

|

If you've constructed electronic circuits before and got

away without using good ESD (anti-static)practice, then be warned,

you won't now. Both the controller and driver use

MOSFETs. When you're constructing the

circuit you MUST use ESD precautions

during unpacking, handling, assembly and soldering

otherwise I pretty much guarantee you will destroy one

or more of the MOSFETS. If you're

not using an ESD Soldering Iron make sure you ground the

tip before soldering each MOSFET.

The

maximum gate voltage on the 2N7000 and MOSFETs in general

is typically +/- 20volts, exceed this in use, or through

ESD and it will fail. A short document on ESD and

MOSFETs can be found

here

I'd also

recommend that you buy a few extra 2N7000's, they're not

expensive and if you destroy one and you've got a spare

it won't ruin your day.

|

Firmware and PICs

The firmware for

both the controller and driver will run on the following PICs.

You will need to assemble the code to produce the correct HEX

file for the processor you are using.

The

Serial RGB Controller code is made up of a single .ASM file

named rgbsync_ctrl.asm and several .INC files. All

these files should be placed in a single directory and the rgbsync_ctrl.asm

file loaded into MPLAB and then

assembled to generate the programmer ready .HEX file. The

SequenceData.inc file contains the RGB, Fade and Hold data for

the sequences. You will probably want to edit this file,

put your own sequence data in it, then reassemble rgbsync_ctrl.asm

to include your own sequence data.

Because the serial

bit rate is generated using the PICs internal RC oscillator it

is imperative that for PIC12F629 and 675 chips, the OSCCAL value

located at the top of program memory is correct and present.

If you accidentally erase the OSCCAL value use this

circuit and code to recover it.

Troubleshooting

On the

Serial RGB Controller , TP1 outputs the bit rate clock which should

be a nominal 2.4Khz. If you have a 'scope or frequency meter to hand you

can verify this.

On the Serial RGB

Controller the signal on GPIO4 (pin 3) of the PIC should

idle at 5V and swing between 0v and 5v when transmitting data.

If the signal on

GPIO4 (pin 3) is correct then before connecting the Controller

TxD output to the Driver RxD input, check the signal at the

drain of the MOSFET Q1 ( TxD connector)

on the Controller to make sure the signal there is going between

0v and 11.4V.

If the TxD output

is okay, connect the Controller to the Driver and then check the signal on the RxD input of

the Driver to make sure the signal is present.

On the Serial RGB

Driver, check that there is serial data being received on GPIO5

(pin 2) of the PIC (using an Oscilloscope). This signal

should idle at logic 1 (5volts) and swing between 0v and 5v when

data is being received.

If this is not the

case for either the Controller or the Driver, and particularly

if the signal is present but not swinging between 0v and 5v,

you've probably got a failed MOSFET.

All the 'faults'

I've had during development have been down to failed MOSFETs,

Connecting Up

The following diagrams illustrate,

schematically

how to connect the controller and drivers together.

- Serial RGB Controller and

drivers using a common PSU (PDF)

- Serial RGB Controller and

drivers using individual PSUs (PDF)

- Connecting drivers to a PC

serial COM interface (PDF)

The serial interface on the

controller and driver boards is deliberately simple by design. It is adequate for connecting multiple

drivers over a short distance. You need to decide whether the

basic serial interface circuit is adequate for you particular

application, and if necessary modify the serial interface circuit to

meet your specific requirements. If you're going to connect a number

of drivers over an extended distance to the serial interface of a PC

or the Serial RGB Controller I'd suggest looking at a solution

based on the RS-485

standard. Driver IC's such as the

ST485CN are cheap enough and would be a a good basis to start

from.

Power Supplies

The controller and drivers need a

regulated 12Volt DC Power Supply. Do not use unregulated

DC supplies - these only deliver the rated output voltage under full

load. You could see as much as 17V at the output of an

unregulated 12V supply under partial load. This will damage the LEDs.

A PSU like the one under part

number 85-2902 from Rapid Online - Rapid Electronics Ltd. is ideal and should run the controller and up to ten

RGB LED PWM drivers, depending the specific LEDs used of course.

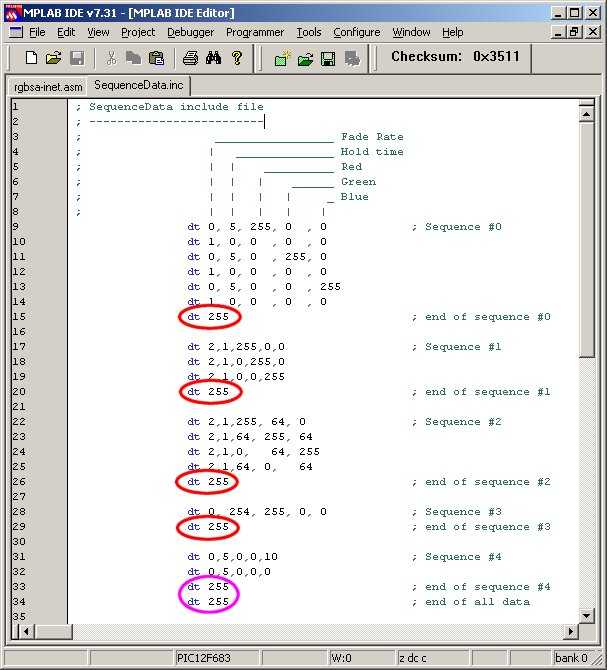

Format of the Sequence Data

The data

used by the Serial RGB Controller for the RGB sequences is held in the file 'sequenceData.inc'

You can edit this file to add, remove or change the data provided.

You must ensure that it follows the format described. In

particular pay attention to the 'end of sequence' and 'end of all

data' markers and also ensure that each line of sequence data

contains five comma separated entries. (see screen dump below)

In the

screen dump above note the

'end_of_sequence' markers circled in red and the

'end_of_all_data'

marker circled in purple.

You must

have at least one sequence present up to a maximum of 256 individual

sequences, although you're likely to run out of available memory on

the PIC before you reach this limit.

-

Each line

of data starts with a 'dt' (data table) assembler directive.

-

All data

is specified using decimal values.

-

Each data value must be separated

by a comma

-

The

sequence data on each line has five fields:

-

Fade

Rate: speed the colours fade from the current values to the new

values. Each step occurs at an interval of 5ms x Fade Rate.

-

Hold

Time: after fade completes, delay before moving to next line of

data. Interval is 50mS x Hold Time

-

Red,

Green and Blue PWM values. 0 = 0% (LED off) through to 255

= 100% (LED fully on)

Typically changes in LED brightness are more noticeable between

0 and 128 than from 128 to 255.

-

End

of the current sequence data is indicated by the Fade Rate field

being set to '255'. When the application encounters this

it restarts the sequence from the beginning.

-

At

the end of all available sequence data both the Fade Rate and

Hold Time fields must be set to '255'

After

editing sequenceData.inc the file should be saved and the

rgbsync_ctrl.asm reassembled. The resulting rgbsync_ctrl.hex

file can them be programmed into the PIC.

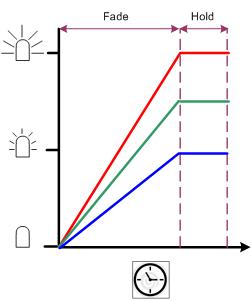

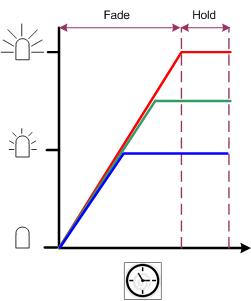

Note about

Fading

In the

previous versions of the code when the LEDs faded from one colour to

another all three LEDs faded at the same rate, as in fig 2.

Neither method is right or wrong, but the behaviour of the fade in

fig 1. is generally how you'd expect it to work. Making

the controller behave like fig 2. is easy to code, making it behave

as in fig 1. needed a bit more thought :-) Anyway, I've given

it some thought and rewritten the code to work as in fig 1.

|

fig 1.

|

fig 2.

|

Saving

the Internal Oscillator calibration instruction.

For

details on the internal oscillator calibration word, download the

Microchip datasheet for the 12F629 / 675 and read section 9.2 and in

particular sub-section 9.2.5.1

This

only applies to the 12F629 & 12F675. The 12F683 uses a

different method for calibration

See my tip to make

sure you will never lose the OSCCAL setting

If you have

erased the OSCCAL setting, use this circuit and code to recover it

FAQ:

-

Editing, adding changing the RGB sequence data.

All the sequence data is now held in the sequenceData.inc file so it

is really easy to add your own sequences. The application

works out how many sequences are present, where they start and

finish and takes care of page boundary crossing. All you have to do

is put the correctly formatted data into the file, save it then

reassemble.

Please take your time when editing the sequenceData.inc file since

errors are likely to cause the RGB Driver to do unexpected things or

crash.

If you see an 'Warning [220]' error during assembly like that shown

below, you've added more sequence data than the PIC has available

memory.

Clean: Deleting intermediary and output files.

Clean: Done.

Executing: "C:\Program Files\Microchip\MPASM Suite\MPAsmWin.exe" /q

/p12F675 "rgbsync_ctrl.asm" /l"rgbsync_ctrl.lst" /e"rgbsync-ctrl.err"

Warning[220] C:\CODE\RGBSA-INET.ASM 158 : Address exceeds maximum

range for this processor.

If you see an Error [112]

message during assembly check for missing comma separators in the

sequenceData.inc file

Clean: Deleting intermediary and output files.

Clean: Done.

Executing: "C:\Program Files\Microchip\MPASM Suite\MPAsmWin.exe" /q

/p12F675 "rgbsync_ctrl.asm" /l"rgbsync_ctrl.lst" /e"rgbsync_ctrl.err"

Error[112] C:\CODE\SEQUENCEDATA.INC 56 : Missing operator

-

Errors caused by

limitations of MPASM

While MPLAB IDE is a Windows application, the MPASM assembler has

its roots in the DOS era and this can cause a number of peculiar

errors when you come to 'quickbuild' the source code.

Error[173] .... Source file path exceeds 62 characters

Windows is happy with a long

file path but MPASM doesn't like anything over 62 characters so

MPLAB IDE will let you create, edit and save to a path like this but

MPASM won't assemble the file.

C:\DOCUMENTS AND SETTINGS\SOMEUSER\PICPROJECTS\ALONGDIRECTORYPATH\SSRGBCTL\RGBSYNC_CTRL.ASM

Error[151] ..... : Operand contains

unresolvable labels or is too complex

This strange error is caused by the '.' in

PIC.CODE

in the file path shown below:

C:\PIC.CODE\SSRGBCTL\RGBSYNC_INT.INC

Take the '.' out like this

"C:\PICCODE\SSRGBCTL\RGBSYNC_INT.INC"

and the code will assemble just

fine.

Contact us:

|