| |

|

|

|

Mini projects |

|

|

|

|

|

- Electronic Die*

Built using a

PIC16F84, about 4 hours worth of code and a few bits on a breadboard. This

was the first time I've worked with PIC's so it was a learning exercise. I

started with the 'Hello World' microcontroller equivalent i.e.

Blinking LED, then tried the 'Knight Rider' sequencing LEDs, and then

hacked this together. The code is written and assembled using the Microchip

MPLAP

IDE V5.70. I only did this as an exercise to familiarise myself

with PIC assembler, but having got it working I decided I wanted it

smaller and as I had just acquired some 12F675s I took the original

16F84 code and developed it further to work with the 12F675.

For those of you who don't know, and to save

you the trouble of sending me an email to point out your

ignorance, dice is the plural of die

see here.

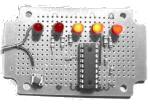

LED die using

PIC16F84 Die on bread board,

and

Programmer (the neat

PCB to left) with Die breadboard foreground and my circa 1985 Computer

PSU, modified to get supply for PIC programmer. The assembler code

was written to work, not as an example I'm afraid, so no apologies for the

quality. I haven't done any further work with this since I

decided the 8pin PIC12F675 was better suited for building a miniature

die. You should also note that if you do build a die using

the 16F84 code below it is flawed in that it throws with unequal

probability.

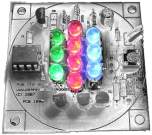

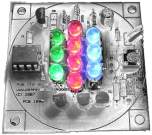

LED die using PIC12F675. Starting with the 16F84 code above I've modified and developed it

further to run on an 8 pin 12F675 device.

This device has an internal 4Mhz oscillator so it needs no external

support components and results in this minimum part die.

I got this PIC for £0.99p so I reckon you can build the whole

thing for about £2.50. You don't need a power switch since

the PIC 'sleeps' between throws and uses just a few micro Amps in

this state.

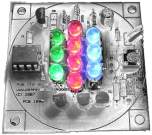

- PCB Artwork

Three months after I built these prototypes I finally got

round to producing a PCB for the die. The artwork is

available from the link below. Rather than using

discrete resistors the PCB layout uses a 9 pin 270R SIL resistor

pack (Actually only needs an 8 pin one, the PCB will accommodate

either). When you fit the button cell battery holder, check

to make sure it doesn't short out any of the component leads

behind it. You do need to use high efficiency LEDs with this

otherwise they won't be bright enough and if you increase the

current by reducing the value of the resistor pack it will impact

on battery life.

The artwork above is the second revision of the PCB. The

photo's below show the die built on the first PCB version I did.

This is pretty much identical to the second, I just manually

tweaked some of the auto routed tracks and removed the connector

for an external power connector.

Top image. Bottom

image

-

Operation

When the die first starts after power

is applied it initialise the device and then goes to sleep until the SW1 'roll'

button is pressed. While the button is pressed the display is

blank. On releasing the button the LEDs 'spin' for about 5 seconds.

The 'throw' is then display for 20 seconds at the end of which the

LEDs fade down and turn off over about 2 seconds. If the throw button

is pressed during this time, the die throws again, otherwise after 22

seconds the die goes back to sleep. I've built four of these

die, all running from CR2032 3V lithium cells. One of these

which I keep on my desk is still working on the original battery after

15 months.

Here's an Ultra Small

Die that I've built using a 12F675. This would be ideal

for a surface mount design but I

haven't gone that far with it.

This is built on an tiny bit of strip board, with some careful assembly

and creative use of a baked bean can I've got down to the size of a 50

pence piece.

-

Front

View,

-

Rear View

before attaching battery holder

-

Completed with

battery holder attached (made from lid of Baked Bean can) attached.

-

Third

one with SM battery holder, PIC soldered directly into

circuit.

| March 2007

For some reason the 16F690 PIC

seems quite popular so here's yet another version of the die

using that PIC. While making the necessary

changes to the 12F675 code for it to run on a 16F690 I also

cleaned the original code up a bit and made it easier to

change LED and switch port pins so you don't have to dig

through the code to do it.

Source ASM and .HEX files

can be downloaded here die690inet.zip

Sorry, no schematic for

this. Use the one for the 12F675

here but make

connections to the 16F690 as shown below. Because we have

plenty of pins on this PIC, if you have a programmer with an

ICSP connector, you can hook it up directly using the pins

shown, if you don't ignore it.

__ __

[ICSP 5V ] Vdd -|1 20|- Vss [ICSP Ov ]

n/c -|2

19|- n/c [ICSP CLK ]

[ICSP Vpp] n/c -|3 18|- n/c [ICSP DAT ]

n/c -|4

17|- SW1

n/c -|5

16|- n/c

LEDA -|6 15|-

n/c

LEDB -|7 14|-

n/c

LEDC -|8 13|-

n/c

LEDD -|9 12|-

n/c

n/c -|10 11|-

n/c

-----

n/c -> no connection

[ ICSP aaa ] if you want to program the PIC using

ICSP

|

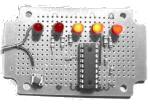

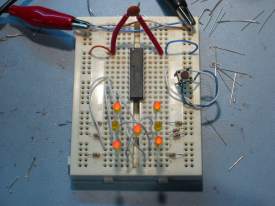

Running on my bread board.

The LEDs look a bit dim here as I was testing with a 3 volt

supply but the resistors were selected for 5 volts.LED

Arrangement for die display

B C

D A D

C B |

-

Electronic Dice,

I

designed and built this around 1985 using discrete 7400 series TTL

logic. I found it while digging out all the useful stuff

that has laid around since I last played with electronics in the early

1980's. I show it here just out of interest.

-

12F675

as Flip Flop Code to

make a 12F675 operate as a D-type or JK-type flip flop Since

I implemented a D type flip flop using the PIC Logic Elements I

thought I might go the other way and implement an entire D type

flip flop in a single PIC. This uses the edge triggered and

port change status interrupts and was an opportunity to have a play with

interrupts on the PIC. As

written this code will cause a PIC to function as a negative edge

triggered D type flip flop with active low Set and Reset inputs.

'D' type flip flop

Following the D type flip flop I've

hacked it round to make a JK flip flop. This implementation has one

extra 'feature' that a normal discrete logic device doesn't

have. After a reset, port GPIO5 (pin 2) is read and the logic level

used to select either a positive or negative clock edge.

GPIO5 = 1, negative edge (GPIO5 uses weak pull-up, so no

external resistor is needed)

GPIO5 = 0, positive edge

'JK' type flip flop

This circuit receives the signal from a

IR remote control, like those used to control your TV or DVD player and

allows the signal to be repeated in another location.

To get a 40Khz carrier requires an output to be toggled

on and off 40,000 times a second, which means the code needs to execute in

1,000,000/40,000 instruction cycles; this gives a very tight 25

instructions in which to do the job. Fortunately it's an easy job to do

so most of the instructions are just used to waste cycles. It's

not easy to get an accurate frequency with so little time and few

instructions cycles to play with but the IR receivers will work

several Khz either side of their design detection frequency so it's not

a problem.

This code can generate a 40Khz, 38.4Khz

or 37Khz carrier with a ~15% duty cycle. The frequencies are configurable in the source

code such that once programmed GPIO5 input on the PIC allows the

selection of two frequencies. By default the code is set to

produce 40Khz and 37Khz carriers which are modulated by the logic level

on GPIO2. This would generally be connected to a IR decoder IC.

One thing I did find with the Sony

equipment (I haven't tested it with anything else), 875nM IR LEDs don't

seem to work, but the 950nM one specified works well. (TSUS5400, Mfg

Vishay. Available from Farnell,

part number 178302)

Rapid Online - Rapid Electronics Ltd.

(See

big LED version here)

My nephews got a

Scalextric

slot car racing circuit from Santa for Christmas. This was a blast-from-the-past for my brother and me and we were soon showing the

kids how to race. However it quickly became apparent that

"3-2-1-Go" wasn't the best way to start a race so I put this

together to simulate the gantry lights used for starting F1 motor races.

When the circuit is first powered on

LED's D2 and D4 light just to indicate the circuit is operating.

When the start button (SW2) is pressed

all the LED's turn off. They then illuminate sequentially at one second

intervals until all five LED's are on. After a random interval

between 0 and about 7 seconds the LED's extinguish, signaling the start

of the race.

Once the LED's have extinguished simply

press the start button again to initiate another race start

sequence. While waiting for the start button to be pressed the PIC

is put into a sleep state. This drops the current consumption to

around 10uA

Notes:

-

The circuit is really quite

simple. I tested it on a breadboard with standard 5mm red

LED's using 220R resistors from a 5Volt supply. The one on

the prototype board operates at 3Volts using two AA

cells. I dropped the value of the LED current limiting

resistors to 150R for this since the LED's I used weren't

hi-efficiency types. If you can use hi-efficiency LEDs you

could probably use 270R or 330R resistors and operate it

from a CR2032 3Volt Lithium coin cell.

-

With all five LEDs on,

the

prototype circuit was drawing about 25mA from a 3V supply. This

drops to a meagre 10uA with all LEDs off which should allow the

circuit to operate for many months, or even years depending on

use, from a couple of AA

cells without the need for a power switch.

-

The code enables weak-pull up on

the Port B pins but the unused Port A pins are all configured as

inputs and need pulling down to Vss.

-

The interval between each LED

turning on is

consistent and approximately 1 second. Timing is done

using the internal timer which in turn runs from the internal

clock. I'm happy that it's good enough for this application but

if millisecond accurate timing is needed (I can't think why)

you'll need to look elsewhere.

A new version of this circuit that can

be used with Scalextric Sport and similar slot car tracks has jump-start

detection. Full details are here

Now have their own pages.

Click here for the

RGB LED PWM Controller

Click here for the

Serial controlled RGB LED PWM Driver

Click here for the

High Power RGB LED PWM Driver

Click here for the

Addressable Serial Controlled RGB LED PWM

Driver

This code runs on a PIC

16F627A or 628A (and A.F.A.I.K 627/628 parts). It uses the serial

USART on the PIC to communicate with a PC. Through this a simple CLI

(Command Line Interface) is implemented that allows commands to be sent

to the PIC to control output lines and read and return the status of

inputs on the PIC

The serial interface is

configured to operate at 9600bps, 8bits, No Parity, 1 stop bit.

Port A is configured as

the output port, not forgetting that RA4 is an 'input only'. Port

B is used as the input port, again RB1 and RB2 are used by the PIC USART

so aren't available. In addition I have reserved RB0 for a Dallas 1-wire

interface. Although the code isn't implemented here, the RB0 port along

with RB1 and RB2 is masked from the input status command so bits RB2,1,0

always return 0.

To summarise;

Outputs are RA0-3, RA5-7

Inputs are RB3-7

The CLI commands and

functions are described below:

;

; Code displays the following message after a reset

; 'PIC Serial IO controller ready'

; A '#' is used as the command prompt.

; A '?' is sent to the terminal when any command is either not

; recognised, or contains invalid or insufficient arguments.

;

; Commands (All commands are lowercase except the Restart command)

;

; v - display firmware version

; i - display value on input port

; o - display value of outputReg variable (see below)

; nx - set output bit x

; fx - clear output bit x

; tx - toggle output bit x

; where x is in the range 1 to 8 or 0 to operate on all bits simultaneously

; sxxxxxxxx/ - set output to bit pattern specified by xxxxxxxx mask

; where x must be 0 or 1. MSB is leftmost.

; All 8 bits must be specified and must terminate with '/'

;

; c - Continuous monitor and display of the input port

; . - Stop continuous monitor of the input port and return to command prompt

;

; m[io] - Toggle port value display format [ i = input, o = output ]

; displays port value as hex 'HH' or binary 'bbbbbbbb' MSB leftmost

; At startup the format will be hex.

;

; p[io] - Toggles between displaying the port status only, or printing a text string

; followed by the port status.

; e.g. with text "Input status : A5", without "A5"

; At startup print mode will be port status only, no preceding

text.

;

; w[ed] - Enable or Disable the weak pull-up feature on Port B

; Weak Pull Up is disabled at startup.

;

; R - Do a software restart (note: Uppercase R)

;

;

; Note: All output commands work on the outputReg memory variable.

; This is copied to the output port register on completion of each command.

; The show output port command does not read the port register, it reads

; and displays the value in the outputReg memory variable.

Screen

dump of a sample terminal session

-

Source

Code (ZIP archive)

-

Hex (right-click Save As) for 16F627A (also

tested with 16F628A)

Notes:

-

There are no schematics for this

since it's designed as a building block. You will need to

interface pins RB1 and RB2 to a serial interface. RB1 is RXD input

and RB2 is TXD output. The code configures the PIC to use the

internal 4Mhz oscillator so no external crystal is needed.

-

You can use a MAX232 or one of the many variants, to interface to a

PC serial port. However, the schematic and PCB layout shown here for a

simple

discrete RS232 interface is cheap and and easy to construct and I've found

it works

well, or rather I've not found anything it hasn't worked with.

(I found the circuit design on the Net, I changed the transistors

for types I had in my parts box and in fact you can use pretty much

any general purpose NPN / PNP transistors here)

-

There are numerous applications and

languages that can be used to communicate with and issue commands to

the controller via a PC serial port. I've used a free

software terminal emulator called TeraTerm

while developing the code. The TeraTerm application also

features an easy-to-use macro command language that can be used to

automate the controller.

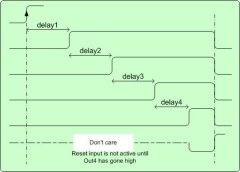

This code will

work with a 12F629, 12F675 or 12F683.

A rising edge on

the Trigger input starts a delay timer. At the end of the delay

period Output 1 goes high and a second delay timer is started.

At the end of the second delay Output 2 goes high. This is

repeated for Outputs 3 and 4. The result is four outputs that go

high in sequence with user defined delays between each one.

Once Output 4 has

gone high, a high level on the Reset input causes all four

outputs to clear and the program goes back to the initial state

waiting for a rising edge on the trigger input.

Each delay is

independent and configurable. The delay can be set either

to a period of 0 to 255mS in 1mS intervals, or a period of 0 to

25,500mS in 100mS intervals.

If the Reset input

is tied high, the code will automatically reset as soon as Out4

goes high.

|

|

The four delay periods are

set by constants at lines 74-77 of the ASM file.

Each of the four delays

can be set to multiples of 1mS or 100mS. To do this you will need

to edit the .ASM file at the following lines. You can have a mix

of 1ms and 100mS delays depending on your requirement.

-

Delay1 edit line 137

-

Delay2 edit line 148

-

Delay3 edit line 159

-

Delay4 edit line 170

The download ASM file is

set for 1mS delays. To use 100mS delays, edit the call changing

_Delay to _LDelay

then reassemble the file.

call _Delay

; call 1mS delay function

; change _Delay above to _LDelay for delay with

100mS intervals

The code was produced

after I was contacted by someone who need a PIC to do this. They only

needed two outputs but to make it more useful I've added the two extra

outputs and the Reset input.

|